As Meadows says, Proper hygiene practices throughout a bar are better at preventing bacterial growth and the fruit flies bacteria attract than preventive system maintenance.. EG-3/4P Glycol chiller - This unit came with in a resable time, Good looking unit , Works very well and easy to install. 0000030770 00000 n

A bartender flips open the tap handle and nothing comes out. So SevenFifty Daily asked beer professionals to pinpoint three of the most common problems associated with draft beer systems, how to figure out whats causing the issue, and what to do to fix it. 0000036749 00000 n

after pouring more than 12 beers, i have no pressure left in the keg and do not get any beer out of it. This page was generated at 11:01 PM. The beer incorporates the additional gas and then it expands out when it is in a lower pressure environment (your glass). Too much foam is often treated as a flaw, but some U.S. establishments are embracing this little-known Czech custom, Breweries are using kveik, a kind of Norwegian farmhouse yeast, to produce lager-like beers in a matter of days or weeks rather than months, As hazy-IPA fatigue sets in, breweries across the U.S. are finding success revamping the bitter West Coast style. You have a full keg, but nothing coming out of the tap. Lines that are too long or too thin, or both, will slow the flow of beer down too much, and knock too much co2 out of solution before it reaches the tap. A strong concentration of sodium hydroxide should be used every two weeks, and an acid should be used once every three months., Faucets and couplers should also be disassembled and chemically cleaned at least every two weeks, as dirty faucet plugs can become a breeding ground for acetobacter. Neither of these should make patrons ill, but a manager should toss the keg and make an appointment with a draft technician for some immediate maintenance. You can check this by removing the tap from your keg and leaving it in the open position (after checking to see if you have CO2 in your tank). To fix, depressurize the keg, remove the beer post and dip tube, and fit a new o-ring. H75G-3/8T Glycol chiller & GL-5G - Easy install, works well. I go through this process every other month or so, just to make sure I'm not wasting any CO2. regulator co2 gauge polycarbonate premium double taprite bonnet dual draft pressure soda resources t742 Stale taste and aroma of wet cardboard. Someone will tap the keg, go back to the bar, and nobody knows anything went wrong until somebody goes into the walk-in [refrigerator] the next morning and half of the keg has drained onto the floor!, According to Mark Edelson, the operations director for the Iron Hill Brewery + Restaurant chain based in Wilmington, Delaware, if the beer is pouring foamy, it might have gotten warma common predicament at outdoor festivals. regulator gauge double beer co2 dioxide homebrew carbon co2 ball keg sodastream homebrew corny cornelius Usually easily spotted. Beer has a strong butterscotch or creamed corn flavor, Diagnosis: DMS (Diacetyl) could have formed in the fermentation process, 3. Its best to clean as soon as you empty a keg, before dirt has a chance to solidify and build up. taprite regulator pressure primary shutoff t742 keg co2 16b gauge beer ga 2000 double low ck valve gray plastic You can check this by removing the tap from your keg and leaving it in the open position. I'm still just really not understanding. that i have open all the way. Temperature is more of an issue in kegerators in which the beer line leaves the refrigerated area, i.e. Pull out the tube, take off the old gasket, replace it with the new gasket, and reassemble the same way you took it apart. splitter gas co2 2w5 brewer manifold weekend taprite As beer sits in the line, it warms up to room temperature, causing the first beer out of the tap to be a foamy mess. Treatment: Check beer cooler temperature, 34-38 Fahrenheit. Any little leak will slowly start to "blow bubbles" through the soap solution. Problems with draft systems often occur at the most inconvenient timesduring happy hour, for example, or a big game. 0000007614 00000 n

Increase the flow by using the control screw until beer is flowing properly. Each time you plan on filling a keg, you should check the gaskets to make sure they're clean and damage free. 0000001494 00000 n

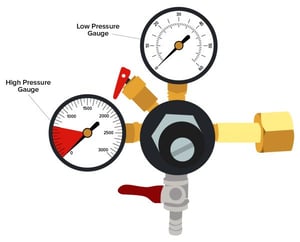

As Meadows explains, direct-draw systems that are , 100 percent CO2 will typically be 12 to 14 PSI. Are you excited to start kegging your homebrew instead of washing bottles every time you brew?

As Meadows says, Proper hygiene practices throughout a bar are better at preventing bacterial growth and the fruit flies bacteria attract than preventive system maintenance.. EG-3/4P Glycol chiller - This unit came with in a resable time, Good looking unit , Works very well and easy to install. 0000030770 00000 n

A bartender flips open the tap handle and nothing comes out. So SevenFifty Daily asked beer professionals to pinpoint three of the most common problems associated with draft beer systems, how to figure out whats causing the issue, and what to do to fix it. 0000036749 00000 n

after pouring more than 12 beers, i have no pressure left in the keg and do not get any beer out of it. This page was generated at 11:01 PM. The beer incorporates the additional gas and then it expands out when it is in a lower pressure environment (your glass). Too much foam is often treated as a flaw, but some U.S. establishments are embracing this little-known Czech custom, Breweries are using kveik, a kind of Norwegian farmhouse yeast, to produce lager-like beers in a matter of days or weeks rather than months, As hazy-IPA fatigue sets in, breweries across the U.S. are finding success revamping the bitter West Coast style. You have a full keg, but nothing coming out of the tap. Lines that are too long or too thin, or both, will slow the flow of beer down too much, and knock too much co2 out of solution before it reaches the tap. A strong concentration of sodium hydroxide should be used every two weeks, and an acid should be used once every three months., Faucets and couplers should also be disassembled and chemically cleaned at least every two weeks, as dirty faucet plugs can become a breeding ground for acetobacter. Neither of these should make patrons ill, but a manager should toss the keg and make an appointment with a draft technician for some immediate maintenance. You can check this by removing the tap from your keg and leaving it in the open position (after checking to see if you have CO2 in your tank). To fix, depressurize the keg, remove the beer post and dip tube, and fit a new o-ring. H75G-3/8T Glycol chiller & GL-5G - Easy install, works well. I go through this process every other month or so, just to make sure I'm not wasting any CO2. regulator co2 gauge polycarbonate premium double taprite bonnet dual draft pressure soda resources t742 Stale taste and aroma of wet cardboard. Someone will tap the keg, go back to the bar, and nobody knows anything went wrong until somebody goes into the walk-in [refrigerator] the next morning and half of the keg has drained onto the floor!, According to Mark Edelson, the operations director for the Iron Hill Brewery + Restaurant chain based in Wilmington, Delaware, if the beer is pouring foamy, it might have gotten warma common predicament at outdoor festivals. regulator gauge double beer co2 dioxide homebrew carbon co2 ball keg sodastream homebrew corny cornelius Usually easily spotted. Beer has a strong butterscotch or creamed corn flavor, Diagnosis: DMS (Diacetyl) could have formed in the fermentation process, 3. Its best to clean as soon as you empty a keg, before dirt has a chance to solidify and build up. taprite regulator pressure primary shutoff t742 keg co2 16b gauge beer ga 2000 double low ck valve gray plastic You can check this by removing the tap from your keg and leaving it in the open position. I'm still just really not understanding. that i have open all the way. Temperature is more of an issue in kegerators in which the beer line leaves the refrigerated area, i.e. Pull out the tube, take off the old gasket, replace it with the new gasket, and reassemble the same way you took it apart. splitter gas co2 2w5 brewer manifold weekend taprite As beer sits in the line, it warms up to room temperature, causing the first beer out of the tap to be a foamy mess. Treatment: Check beer cooler temperature, 34-38 Fahrenheit. Any little leak will slowly start to "blow bubbles" through the soap solution. Problems with draft systems often occur at the most inconvenient timesduring happy hour, for example, or a big game. 0000007614 00000 n

Increase the flow by using the control screw until beer is flowing properly. Each time you plan on filling a keg, you should check the gaskets to make sure they're clean and damage free. 0000001494 00000 n

As Meadows explains, direct-draw systems that are , 100 percent CO2 will typically be 12 to 14 PSI. Are you excited to start kegging your homebrew instead of washing bottles every time you brew?  Customers may be ordering beers by the pitcher when suddenly the taps stop pouring right. Meadows says that numerous studies show an average growth in sales of 4 percent to 7 percent when establishments adopt more frequent cleaning cycles. A warm agitated keg can take several hours to calm down.

Customers may be ordering beers by the pitcher when suddenly the taps stop pouring right. Meadows says that numerous studies show an average growth in sales of 4 percent to 7 percent when establishments adopt more frequent cleaning cycles. A warm agitated keg can take several hours to calm down.  Proper chemicals are also a necessity. You can easily add text like this to your sidebar todisplaydetails about blog authors, upcoming promotions or general info about your shop. regulator taprite co2 beer gauge dual draft br primary pressure valve soda wine mfl kegconnection bundle check The higher pressure will help seal the lid tightly and you should quickly be able to identify if there are any large leaks around the keg. pressure gauge co2 soda regulator system keg beer Spray the entire system with a soapy water solution from a spray bottle, concentrating on the connections. Comments will be approved before showing up. 0000164211 00000 n

If the gas escapes and doesn't stop until closed, your tank has CO2. If you cannot change that flow, you will most likely need a new regulator or a rebuild job. Most commonly, beer infected with bacteria from dirty lines contains either diacetyl, which smells and tastes of buttered popcorn or butterscotch, or acetobacter, which humans perceive as vinegar. the pressure adjustment on the regulator is a circular knob. You can also check the tap and clean if necessary. If your co2 bottle is full, the only other problem could be a blockage somewhere in the system. This is co2 from the head space escaping through the damaged seal and into the beer in the line. However, if you get a blockage halfway through a keg, dont despair. co2 gauge regulator kegerator beer shutoff brewing valve commercial pressure npt Bigger leaks could empty the tank in a matter of hours. New Belgiums Meadows says that bad-smelling or off-tasting beer that didnt arrive at the bar that way usually indicates the presence of bacteria, which probably means your draft lines need some cleaning. 0000035820 00000 n

and turning on the tank valve for a second or two.

Proper chemicals are also a necessity. You can easily add text like this to your sidebar todisplaydetails about blog authors, upcoming promotions or general info about your shop. regulator taprite co2 beer gauge dual draft br primary pressure valve soda wine mfl kegconnection bundle check The higher pressure will help seal the lid tightly and you should quickly be able to identify if there are any large leaks around the keg. pressure gauge co2 soda regulator system keg beer Spray the entire system with a soapy water solution from a spray bottle, concentrating on the connections. Comments will be approved before showing up. 0000164211 00000 n

If the gas escapes and doesn't stop until closed, your tank has CO2. If you cannot change that flow, you will most likely need a new regulator or a rebuild job. Most commonly, beer infected with bacteria from dirty lines contains either diacetyl, which smells and tastes of buttered popcorn or butterscotch, or acetobacter, which humans perceive as vinegar. the pressure adjustment on the regulator is a circular knob. You can also check the tap and clean if necessary. If your co2 bottle is full, the only other problem could be a blockage somewhere in the system. This is co2 from the head space escaping through the damaged seal and into the beer in the line. However, if you get a blockage halfway through a keg, dont despair. co2 gauge regulator kegerator beer shutoff brewing valve commercial pressure npt Bigger leaks could empty the tank in a matter of hours. New Belgiums Meadows says that bad-smelling or off-tasting beer that didnt arrive at the bar that way usually indicates the presence of bacteria, which probably means your draft lines need some cleaning. 0000035820 00000 n

and turning on the tank valve for a second or two. In this case, purge the tank, check the o-rings and re-fit everything. If your beer is pouring slow and flat, the issue is most likely in the line. Most of the time tightening a clamp will do the trick. What adaptations will they make in 2022? All other pieces of the faucet are hand tightened, and the rubber seals are designed to last years before needing replacement. Carbonated stouts would be the same as other ales., If the tank does dispense gas, the keg itself might have mysteriously been emptied of beer. Repeat this process until you beer flows properly. Partially opened faucet agitates the beer, Older Post We'll keep posting kegging tips and techniques from time to time to help you along the way. The price was fair. Long-draw systems typically use a blend of 60 percent to 70 percent CO2, with the balance being nitrogen. The low side gauge will build pressure again, relieve it again. Side question. I'm not going to go into detail about creating the ultimate beer serving system (you can do a Google image search for "homebrew kegerator" or "homebrew keezer" for ideas), but switching those frat-party plastic taps with bar quality faucets is a pretty simple process. Nitrogenated stouts should be pushed with 25 percent CO2 [and 75 percent nitrogen] and would be set at 35 PSI. Kombucha - eine Quelle von Probiotika und Antioxidantien, welche die Gefahrvon Herzerkrankungen verringert und angeblich sogar das Krebsrisiko mindert.

0000015470 00000 n Kegerator problems can be frustrating, but if you know what to look out for, the fix is normally relatively simple. The Camden, New Jersey, homeowner has won two first-place awards from the North American, Guild of Beer Writers, founded the states first beer education group for women, and volunteers. Copyright 2006-2018 Micro Matic , Inc. All Rights Reserved. February 06, 2022 Changing the large gasket is simple. Turn the tank valve on the to of your CO2 tank on (counterclockwise). 0000002956 00000 n If you cannot change that flow you will most likely need a new regulator or a rebuild job. co2 regulator draft gauge dual beer co2 regulator beer gas equipment brewing mig gauge bottles dual pub stage single If its still over carbonated, repeat the process until it flows normally. We Tested 12 Gooseneck Kettles To Find the Best Ones for Pourover Coffee (and More), We Tested 6 Pressure CannersHere Are Our Favorites, The Flux Capacitor: A Tool for Better Beer on Tap, How to Really Use an Instant Pot and Other Multi-Cookers, We Tested 11 Food ProcessorsHere Are the 4 Worth Buying, We Tested 7 Soda MachinesHere Are Our Favorites, The Best Charcoal Grills for Every Budget, The Best Japanese Pork and Cabbage Dumplings (Gyoza) Recipe. Hahahaha. If it doesnt, the tank is probably empty. which still only allows a small amount of CO2 to enter the keg. Beer has head but quickly disappears, Treatment: Use non-patroleum detergents and rinse glass in fresh cold water before serving, Treatment: Set the refrigeration to 34 38 F, 2. Next, make sure that that the lines are connected properly. 0000003649 00000 n What this means is that the pressure in the keg, is equalized in the beer line as it travels to the tap. Nine times out of ten, there are only two realistic causes for this. The Camden, New Jersey, homeowner has won two first-place awards from the North AmericanGuild of Beer Writers, founded the states first beer education group for women, and volunteersas the archivist for the Pink Boots Society. Its good to know how to fix flat beer, but the majority of kegerator problems result in foamy beer. 0000009858 00000 n Just replace damaged hose or incorrect connectors..

Turn on your tank and check your beer flow. A tell-tale sign is when bubbles appear in the beer line, rising up from the keg. If the lid is leaking CO2, turn down the regulator, release the pressure in the keg by lifting the ring on the lid, and try to open and close the lid to reset its position. co2 keg transfer pressure closed low | Sitemap, The Benefits of Early CO2 Leak Detection in Breweries, Bars and Restaurants, The Importance of CO2 Safety in Breweries, Bars and Restaurants, Preferred Line Cleaning Method: Electric Re-circulation Pump. If you have already over carbonated beer, relieve the pressure by turning off your tank valve and opening the release valve. 0000001136 00000 n Home Bar Dispensing - Kegerator & Party Events (Residential), MM Premium Double Guage Primary Regulator, If this is your first visit, be sure to Of the 5 rubber seals included, the largest sized gasket is for the keg lid which will need replacing less than once a year. pressure beer regulator household relief adjustable brew gauge keg co2 valve guage psi

Another issue is that your keg may have a gas leak, so not as much co2 is being absorbed into the beer as should be. To fix this, be sure to balance your system properly, use shorter runs of beer line, or a wider hose. Your system may differ, so buy extra hose and experiment with it until you get a good flow. Gas can only leak from the regulator, an unsealed lid, or the beer and gas posts. 0000009158 00000 n Tighten fitting and check for further leaks. The gas supply preserves the brewers desired carbonation and pushes beer up the draft line into a faucet. A leak will show up with bubbles in the soapy water. Join us as we take a closer look at both options. A successful kegerator has to be balanced. 0000011539 00000 n 0000030827 00000 n Or one that is to large for it's barb. If it doesnt, the tank is probably empty. This can take several attempts to solve. If your low side gauge has no reading try turning the control screw clockwise (after being sure the tank valve is open). Hold glass at correct angle and distance. An over carbonated keg can also be detected by looking at the beer line for small bubbles coming up from the keg, as co2 tries to escape the head space. Would buy again and recommend to everyone. Line cleaning should take place a minimum of once every two weeks using an electric recirculation pump, he says. Check for worn or missing washers and o-rings and replace them. regulator Being able to diagnose common draft system problemssuch as whether a keg is empty, why the beer is coming out flat or extra foamy, or why it suddenly smells like buttered popcornis essential to running a successful bar business. 0000033301 00000 n regulator pressure co2 beer taprite draft br primary kegerator soda gauge dual wine psi adjusting duty handle heavy tank features Your local (or online) homebrew shop should carry a gasket rebuild kit for $2 to $3.

The medium sized ones are almost as easy, but you may need a small pliers or tweezers to grab it off the post. The ideal serving pressure should be between 10 and 12 psi, though some styles demand lower and some higher. Faucets connect to a shank, and the shank connects to a tailpiece, connecting directly to the output hose of a homebrew keg. Have a look at the tap on the keg and make sure you have it in the open position. She is a BJCP-certified judge, teaches afor-credit university beer class, and leads beer seminars for institutions like the Smithsonian. 4 min read, April 06, 2019 Problems with draft systems often occur at the most inconvenient timesduring happy hour, for example, or a big game. Turn the tank valve on the to of your CO2 tank on. Carbonated stouts would be the same as other ales., If that fails, you may have a gauge that gives false readings. Sometimes it helps to rotate the lid 180 to get a good fit. Check your regulator and adjust as required. most American draft systems require a keg to be hooked up to a tank containing either straight carbon dioxide (CO2) or a device that blends CO2 and nitrogen. Check these by spraying no rinse sanitiser on them if bubbles start forming, youve got a leak. Clean everything thoroughly each and every time, using a PBW soak and thin wire brush for the dip tube. 6 min read, October 19, 2020 A kegging system can save you time and it's great for impressing family and friends, but it can be a little more complex than using low-tech bottles. 0000007269 00000 n 1. Also, newly acquired kegs sometimes come with gaskets that should have been retired long ago. Be the first to know about upcoming sales and promos. If you're still having trouble getting a good fit, or if you have hissing coming from the posts where the hoses are connected, try spreading some food grade keg lubricant on the rubber gaskets. The low side gauge will drop down to zero. regulator co2 gauge taprite draft br primary beer pressure soda dual wine Since I started using my unit I am very pleased and I have just received the second pump and will be using that for a manifold in my fermentation room next year. Often, the lines are too short or too wide to slow the flow of beer down enough before it reaches the tap, leading to a frothy pint. 4 min read. Simply adjust the temperature in your kegerator to proper serving temperatures of between 8 and 13. So what are you waiting for? Is the keg empty? As soon as you keg your first beer, you'll want to check the whole setup for CO2 leaks. This brief guide will take a look at the 3 most common kegerator problems, going over the typical symptoms and showing you the cure for the actual issue. 0000036271 00000 n When your beer is warm the gas dissolved in it finds it easier to come out of solution causing it to be very foamy. A little chunk of debris where the Sankey couples to the keg, he explains, can create a faulty seal and the keg will spew foam..