This technology needs to break through the following fact: 1) The quality of the casting as an integrated block should be high. Hydraulic valves are available in a variety of sizes and according to multiple International Standards. Special hydraulic valve is based on normal hydraulic valves for the further meet certain specific requirements and development. These valves maintain the pressure as entered manually by the operator. A directional control valve comprises at least two-spool positions and two working ports. DTA is serving your industry with the supply of hydraulic parts and hydraulic components for more than 25 years. This can be used as a flow meter by measuring the pressure drop across the orifice. Mostly all valves have the same structure a valve body, valve spool, and components of driven valve spool movements. Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. Advantages of the integrated block In addition to the advantages of the modular valve, the valve is bolted to the manifold, so that it is not necessary to remove the pipe one when replacing the valves, and the connecting pipe and the corresponding pipe joint reduce due to the integrated block: A potential risk of external leakage reduce; The working space and weight occupied by a system reduce; The pressure loss of a pipeline reduced, and the heat also reduce; The vibration resistance of a system increase and the reliability of system operation is also increasing; The response time of a system can be significantly shortened; A reduction in assembly time and cost; An integrated block can not be assembled on-site, and the failure rate can be greatly reduced; Due to the use of the integrated block, the control valves are relatively concentrated, which also facilitates repair. Hydraulic valves are used in hydraulic power packs to direct the fluid to and from the cylinder. Different valves function in different ways. After receiving the circuit diagram and technical requirements provided by the customers, the manufacturer can complete the design of the integrated block within a few days. Save my name, email, and website in this browser for the next time I comment. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. The valve spool is manufactured a plurality of annular shoulder groove, according to its requirement function, it is called shoulder between the valve housing and spool annular groove. Here we list some of the classes for directional-control valves. The hydraulic valve relieves the pressure on the pump or lowers the temperature of the oil before it enters the hydraulic circuit. 3- Touch rain, seawater, or other corrosive liquids? 8 hours/day, or not? Variation range? Size? The valve is a more ideal control element in the real-time control of the electro-hydraulic system.

These valves are used in the hydraulic section where flow or pressure is needed to be varied. The directional control valve is used to pass on the pressure medium (i.e. In this valve, the flow is controlled by changing the flow area of the port. The proportional valves are operated by using DC power.

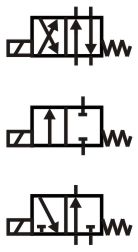

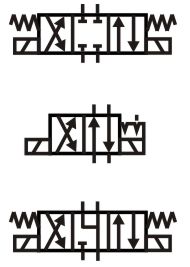

These valves are used in the hydraulic section where flow or pressure is needed to be varied. The directional control valve is used to pass on the pressure medium (i.e. In this valve, the flow is controlled by changing the flow area of the port. The proportional valves are operated by using DC power. Radiation? How strong is it? B. Modular valves The modular valve is installed by subplate mounting and several valves can be installed together by modular or sandwich, with bolts to achieve different hydraulic circuits. The 2-way directional control valve is the simplest directional control valve that has two ports called inlet and outlet. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. The cartridge valve parts are simple, manufactured as per requirement standard to valve sleeve, spools, seat, spring or sealing rings. How high is the economic speed? The valve part that drives these flow control components is known as the actuator or operator of the valve. But its disadvantages are apparent: 1) Dispersed components, ample working space 2) There may be more leaking points 3) Not easy to assemble and disassemble. All Rights Reserved. B. Rotary valves The valve spool is cylindrical type, there are inlet and outlet ports on the valve housing and grooves on the valve spool. There are many types of hydraulic valves available in the industry. Some hydraulic applications require an individual valve, whereas more complicated hydraulic systems could use a combination of valves to complete its function. The pressure is created because of some flow restriction, if this not checked then it would create many problems in hydraulic components. High precision is needed while the operation and it must not be influenced by outside interference. Such as IS04401 (IS04401 PDF File Download) is widely accepted. Flow control valves are used for controlling and adjusting the fluid or gas flow through the system. The valve is suitable for flame-retardant and explosion-proof requirements hydraulic system. If mounting dimensions of a manifold or subplate manufactures by clients, it can produce according to the size of the valve, the mounting surfaces of various modular hydraulic valves have been standardized nowadays, like CETOP, NFPA, ISO4401, DIN 2430 standards. Working Principles,Types & Function, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2022 Updated). There are many types of pressure control valves they are pressure relief valve, pressure reducing valve, pressure sequencing valve, pressure unloading valve, and counterbalance valve. The reversing valves change the flow direction and they cut off or connects oil channels by the relative motion of valve core in the valve body. 7-Voltage range of supply voltage? For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors. A. Multi-block directional control valves Multi-directional valve referred to as spool directional control valves, is combined more than two valve sections as valve main valve, with directional control valve, pressure relief valve and check valve as one multi-function combo valve.

As a designer must and should do their best to meet these requirements, but also should realize to figure out what to ensure first. The valve is widely used in the industry area, but it can be only mounted along pipelines, which may cause more oil leakage spots and inconvenient for hydraulic system maintenance. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. Or speed curve? The spool of the valve can be rotated and controls working oil port on or off, to achieve fluid flow direction, pressure and flow control. No matter the type of valve or the application, PHC has a comprehensive inventory of valves from a range of brands. The further standard hydraulic valve can be mounted on each side of manifold (Each manifold side is like a connection subplate), the oil flows inside the valves and manifold channels to control hydraulic force, the manifold design is being able to save mounting space in the hydraulic system and without hydraulic pipes to save the cost. D. Electro-hydraulic servo valves Electro-hydraulic servo valve is called a servo valve as well, is to accept electrical analog control signals and output the analog liquid power valve. D. Valves future working environment 1- Indoor, open-air work?

As a designer must and should do their best to meet these requirements, but also should realize to figure out what to ensure first. The valve is widely used in the industry area, but it can be only mounted along pipelines, which may cause more oil leakage spots and inconvenient for hydraulic system maintenance. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. Or speed curve? The spool of the valve can be rotated and controls working oil port on or off, to achieve fluid flow direction, pressure and flow control. No matter the type of valve or the application, PHC has a comprehensive inventory of valves from a range of brands. The further standard hydraulic valve can be mounted on each side of manifold (Each manifold side is like a connection subplate), the oil flows inside the valves and manifold channels to control hydraulic force, the manifold design is being able to save mounting space in the hydraulic system and without hydraulic pipes to save the cost. D. Electro-hydraulic servo valves Electro-hydraulic servo valve is called a servo valve as well, is to accept electrical analog control signals and output the analog liquid power valve. D. Valves future working environment 1- Indoor, open-air work? M. What is the first requirement? Directional control valves can control the start, stop and change in direction of flow of a pressure medium (i.e. Overall situation 1 The customer (group external or internal? The large-scale integrated block professional manufacturing plant has an annual output of several thousand tons. Is it possible to reduce the risk by marking? Home > Valves > 4 Types of Hydraulic Valves & Their Working Principles. The orifice can be used for flow control it is a device in the shape of a disk with a hole so the fluid will flow through the hole. Looking for Valves Device & Equipment Prices? Because as long as a sand hole appears in a valve hole, the entire manifold is scrapped. C. Sandwich plate valves The sandwich plate valve is developed based on the modular valve, a more compact structure valve. 3- Is hybrid power used to recover braking power? The different types of hydraulic flow control valves are movable flow control valves, pressure compensated flow control valves, fixed flow control valves, and throttling flow control valves. A sandwich plate valve can be used as single valve or hydraulic oil connection, the top and bottom surface of sandwich plate valve is installation surface (Often produced as per standard port pattern), used for valve oil port pattern connection.

Run a negative test? Hydraulic actuators are required when a valve operation needs a large amount of force. The electro-hydraulic valve is a hydraulic servo valve and in this valve, the servo has a device that could be a flapper nozzle or a jet pipe and this device is used to position the servo. This helps to determine speed of movement for the hydraulic actuators. Electrical solenoids have some constraints in producing power, so switching high-pressure hydraulic systems by direct response is impossible. How big is the production volume? Digital valve flow rate is at a very small, therefore, it can only be used for small flow control applications, such as the electro-hydraulic control valve pilot control level. Coupling solenoid with pilot actuation allows the solenoids to switch lower pressure pilot operations to control higher pressure ports. Required performance Mechanical? post-graduate in Electronics & communication. The hydraulic system with a modular hydraulic valve will be able to omit many hydraulic pipes, lower problems of hydraulic resistance, oil leakage, surrounding pollution, working vibration, large noise and often maintenance, to the great compact and simplified hydraulic system. A 3-way directional control valve has 3 working ports called inlet, outlet and exhaust. In figure A, the spool is in a position that port P is free to port A, and port B is free to port T. Ports A and B are joined to the ports of the cylinder, flowing through port P, and make the piston of the cylinder to travel to the right. A. Threaded connection valves The inlet and the outlet port of the valve are produced to threaded type, to connect pipe fittings. Hydraulic directional control valves with more complicated characteristics may have multiple gates, as their characteristics allow them to switch fluid within distinct ports depending on the device they supply with hydraulic fluid.