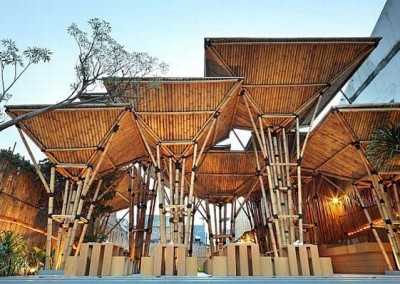

Very strong and lightweight structures can be built using bamboos best property tensile strength with splits. But by treating bamboo, it is possible to make it last decades!Methods for treating bamboo include heat treatment, pressure treating, soaking, or through vertical soak diffusion with a borax/boric acid mix. Bamboo joint with metal anchor. I only use these when strength is of utmost necessity. Any suggestions as to how to join these at the top would be greatly appreciated. It can also be cut into thin strips, flattened, then boiled and dried to create laminated sheets and planks, one form that is currently seeing a huge surge in popularity, not only in China and Japan (which have honed this method throughout history), but also in the Western world. Start adding them to your collection now so that you have them ready when it comes time to build. The two pieces are fit together and then bamboo pegs are used to secure it. Joint with one or two ears. Join TheConstructor to ask questions, answer questions, write articles, and connect with other people. Dendrocalamus Asper splits are used for structural elements and Gigantochloa Apus for non-structural elements. Sign up with your email address to receive news and updates. Instead use nylon, steel or vegetal cord of the appropriate diameter. The worlds best bamboo eco- architecture courses for creatives, designers and architects passionate about bamboo construction and sustainable design. I saw some info about creating strong bamboo joints when using Guadua in building construction, especially adding cement to the joints. Joint with dowels and clamping fitters. TransProfessionals est une compagnie ne en Grande-Bretagne et maintenant installe au Benin. Essentially you are adding a piece of bamboo at a 45 degree angle between a horizontal and vertical piece of bamboo. The starchy material that attracts insects within bamboo can also be removed to reduce infestations or it can be treated by heating in a kiln or over a smoking fire. The pool hang-out pods at the Bamboo U campus is one of the best examples of how to build beautiful woven bamboo structures using splits. Bamboo is a great material to use in construction and after learning a few basic techniques, it can be really easy to build with as well. However, it requires specific techniques to achieve extensive curvilinear forms.

Very strong and lightweight structures can be built using bamboos best property tensile strength with splits. But by treating bamboo, it is possible to make it last decades!Methods for treating bamboo include heat treatment, pressure treating, soaking, or through vertical soak diffusion with a borax/boric acid mix. Bamboo joint with metal anchor. I only use these when strength is of utmost necessity. Any suggestions as to how to join these at the top would be greatly appreciated. It can also be cut into thin strips, flattened, then boiled and dried to create laminated sheets and planks, one form that is currently seeing a huge surge in popularity, not only in China and Japan (which have honed this method throughout history), but also in the Western world. Start adding them to your collection now so that you have them ready when it comes time to build. The two pieces are fit together and then bamboo pegs are used to secure it. Joint with one or two ears. Join TheConstructor to ask questions, answer questions, write articles, and connect with other people. Dendrocalamus Asper splits are used for structural elements and Gigantochloa Apus for non-structural elements. Sign up with your email address to receive news and updates. Instead use nylon, steel or vegetal cord of the appropriate diameter. The worlds best bamboo eco- architecture courses for creatives, designers and architects passionate about bamboo construction and sustainable design. I saw some info about creating strong bamboo joints when using Guadua in building construction, especially adding cement to the joints. Joint with dowels and clamping fitters. TransProfessionals est une compagnie ne en Grande-Bretagne et maintenant installe au Benin. Essentially you are adding a piece of bamboo at a 45 degree angle between a horizontal and vertical piece of bamboo. The starchy material that attracts insects within bamboo can also be removed to reduce infestations or it can be treated by heating in a kiln or over a smoking fire. The pool hang-out pods at the Bamboo U campus is one of the best examples of how to build beautiful woven bamboo structures using splits. Bamboo is a great material to use in construction and after learning a few basic techniques, it can be really easy to build with as well. However, it requires specific techniques to achieve extensive curvilinear forms. But with the right tools you can make building with bamboo go a lot faster.Below is a list of my favorite tools to use when building with bamboo. Some varieties of bamboo are great for structural poles, others would be better used as wall material.

2. Bi weekly guides and content created for the aspiring bamboo designer, architect and creative in mind. The first and most important step of any construction project is to give it a set of good boots, or a strong foundation. The peg should be placed in the column parallel to the rafter. The disadvantage of this jointing technique is the reduction of the strength of the bamboo because of the cutting of the hole. 3.

2. Bi weekly guides and content created for the aspiring bamboo designer, architect and creative in mind. The first and most important step of any construction project is to give it a set of good boots, or a strong foundation. The peg should be placed in the column parallel to the rafter. The disadvantage of this jointing technique is the reduction of the strength of the bamboo because of the cutting of the hole. 3.  They are the predominant way to join two pieces of bamboo together and secure them down. The Induo-Anchor technique is used for bamboos with larger diameters. The recent surge in popularity of bamboo construction is a promising sign for sustainable building and the experimentation with the growth of bamboo outside of its traditional distribution (including a project being conducted in the Mississippi Delta) could only enhance this. Related: How To Propagate Bamboo, By Cutting, Airlayering, and Division.

They are the predominant way to join two pieces of bamboo together and secure them down. The Induo-Anchor technique is used for bamboos with larger diameters. The recent surge in popularity of bamboo construction is a promising sign for sustainable building and the experimentation with the growth of bamboo outside of its traditional distribution (including a project being conducted in the Mississippi Delta) could only enhance this. Related: How To Propagate Bamboo, By Cutting, Airlayering, and Division.  Most people will claim that bamboo doesnt last long, which is true if your bamboo isnt treated. The wall, floor, and roof elements are interconnected and depend on each other for stability.

Most people will claim that bamboo doesnt last long, which is true if your bamboo isnt treated. The wall, floor, and roof elements are interconnected and depend on each other for stability. The nipa hut in the Philippines is one example of a basic bamboo housing structure, with bamboo poles used to support the structure and the walls composed of split and woven bamboo, while in China theres evidence of bamboo-built bridges having stood since at least the 10th century. The result is a curved and flexible element that is adjustable in shape, dimension, and length.

The strength of bamboo largely comes from its integral structure, which means that it cannot be joined used many of the techniques we have traditionally come to know in building using wood. We thread the bamboo culms into the nodes using conical end bolts. Its not only a green solution for the developed world, but a low-cost, readily-available resource in many regions of the developing world where modern building materials are scarce and expensive. During thedrying processthe bamboo diameter shrinks, so when bamboo is used in joinery this will result in lose and weak joints after a few weeks.

Bamboo columns or beams need to have a node atboth ends(or as close as possible towards the ends), if not the pressure of a structure on the joint may crush the bamboo. Shaping and curving whole, hollow bamboo poles in their natural form is challenging because of their cylindrical profile but it can be done using the rup-rup technique. When you join you get additional benefits. Log in to TheConstructor to ask questions, answer peoples questions, write articles & connect with other people. En 10 ans, nous avons su nous imposer en tant que leader dans notre industrie et rpondre aux attentes de nos clients. is the reduction of the strength of the bamboo because of the cutting of the hole. A fast-growing grass, bamboo has been used as a building material since time immemorial. Lidi bundles are used to make both structural and decorative elements.

An untreated bamboo culm has a brief life span and is prone to rot and insect attack. Only if the problem with bamboo joinery can be satisfactorily addressed, andsimplified, we can expect to see much more bamboo in Western buildings, bridges and furniture. Bamboo is susceptible to the detrimental impacts of not only insects, but also rot, fungi and fire, so it does need to be treated both inside and out. If not the bamboo will splinter when struck (for example to position the column). Components of a Planimeter, Low Cost Housing Construction Techniques and Speedy Construction, Types of Foundation for Buildings and their Uses [PDF], Compressive Strength of Concrete -Cube Test [PDF], Procedure, Results, 16 Types of Heavy Equipment Used in Construction, Methods of Rainwater Harvesting [PDF]: Components, Transport, and Storage, Calculate Quantities of Materials for Concrete -Cement, Sand, Aggregates, 15 Factors Affecting the Selection of Construction Materials, Factors Affecting Construction Cost of a Project. This connection increases the speed of construction by eliminating the time required for the fabrication of dowels. Because photosynthesis is at its peak in the middle of the day and high sugar levels are produced in the sap, many believe that dawn or dusk on a waning moon is the ideal time.

2. Lashings, wraps, fraps, and clove-hitch are some knots used in these connections. They dont require fertilizers or pesticides for growth, and their extensive root system helps to draw in and store water, reducing the impacts of soil erosion. The outer surface of the bamboo lacks grip and is very slippery, making connections difficult. With the ever increasing prices of lumber and the immense environmental damage that clear cutting has on an environment, hopefully bamboo will find a way to make it as a building material of the future. A bamboo culm has a round profile which makes the, complicated.

The properties of lidi bundles allow us to bend in 3 dimensions - double curvature. Join now! document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_3" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_4" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_5" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_6" ).setAttribute( "value", ( new Date() ).getTime() ); While we widely use bamboo in various small-scale cottage industries, its use in the construction industry is because of its structural and economic advantages. However, when there is a heavier or structural load on a joint or where two pieces of bamboo comes together, a bolt with appropriate sized nuts would be a stronger alternative. Door, windows, rain gutters, pipes, roof coverings are some non-structural applications of bamboo. Positive fitting connections are widely used in traditional bamboo construction. It is important to keep all these constraints in mind when designing a bamboo joint. Most trees can only be harvested every 25-50 years, while bamboo can be harvested every 3-6 years, depending on the species. To get tighter connections, we use green bamboo strips. The new Green School Bali gym designed by IBUKU is the largest arched structure in bamboo of its kind in the world and is composed of 18 arches, which are built on the ground using the rup-rup technique. Copyright 2022 TransProfessionals.

A Bamboo culm has twice the compressive strength of concrete and equivalent tensile strength of steel, thus making it one of the strongest construction materials. As the fibers in bamboo only grow in the vertical direction, it is not suitable for cross loads. Please enter your email below to receive your free copy of 'The Ultimate Guide to Volunteering Abroad.'.

Bamboo has to beproperlycuredwith a boron miximmediately afterharvesting. Anushri Kulkarni is a 24-year-old, Mumbai based architect with a passion for green architecture. Think post and pier, except with bamboo. This could have a huge impact on deforestation, giving timber forests the opportunity to regenerate in the future. I have been mentioning Bamboo pegs in regards to securing joints used in bamboo construction, but there are a few other methods to secure your joints that you make when building with bamboo.But first, what are bamboo pegs?

A fish mouth joint is traditionally made with a hand saw, round chisel and a carving knife, but I have had good luck using various sized hole saws to do the bulk of the work for me and then I finish it up with a carving knife.Once the mouth is made, it rests under the horizontal piece of bamboo and is pegged together with a wooden dowel. For more info on the online course, please click the link below: Sai joined the Bamboo U team in March 2020 as Research & Development Manager. des professionnels de la langue votre service, Cest la rentre TransProfessionals, rejoignez-nous ds prsent et dbuter les cours de langue anglaise et franaise, + de 3000 traducteurs, + de 100 combinaisons linguistiques, A pan knot space truss comprises two components: a ball knot and thread rods which form the intermediate connection between the central knot and the bamboo culm. Do not use bamboo that hasflourished. I would love to see more detailed info and/or videos about that.

Bamboo joint with wooden anchor. If you do not know what types you have, you can always perform an engineering test to see what types of loads they can handle.Here are some of my favorite types to use when constructing a building. How many cumbersome solutions for joints have one seen, before these materials became a standard in construction?