The blades have a leading edge that is tapered upward, a top edge that is tapered downward, and a trailing edge that is tapered downward. There are two common vacuum cleaner configurations. 3A and 3B are respective perspective and cutaway side views illustrating a conventional impeller. The motor is supposed to run at 3150 RPM, so it was way overloaded. two parallel disks with curved fins mounted between them. (ii) The shroud gap between the bellmouth and the shroud carries less than 1% of the inflow back from the volute to the impeller for the current fans. If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of vacuum impacteller design, you can find the product you want from the vast collection at Alibaba.com. CFD predictions were validated with the measurements. This site requires JavaScript to function properly. vacuum impeller motor cleaner parts 8mm diameter wind hole wheel This type of impeller provides you with top to bottom circulation, and with most energy being converted into a flow. The fan according to the present invention is molded from a rigid plastic such as polycarbonate. The impeller includes a hub for connecting to said shaft, a backplate formed integrally with the hub, and a plurality of blades, formed integrally with the backplate and the hub.

with the dirty-air design and motors drawing about nine or more amperes (amps) of current, the higher 104, pp. The CFD underpredicts the lift pressure for the B#2 impeller which may have resulted from the deviation in geometry used for the calculations and the experiments. The fan for the clean-air design "clean-air" upright, The blades can become chipped, usually at their trailing edge 54, by small hard objects picked up by the vacuum cleaner which hit the impeller with a violent impact. Hence, if the front wall 34 is perpendicular to the volute 36, as is typical, then top edge 52 is perpendicular to trailing edge 54. This way of making the spiral housing was my best method yet. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Suction Motor so that it spins at a very high speed. So without making a new impeller, You can get a pump for residential and large commercial applications from the collection. speed of the fans causes a much higher failure rate. motors contain two or three fan stages pulling in series. America, Identifying Durable Designs & Construction, Vacuum Cleaner Performance Aspects - Menu. Applicant has found that the optimum balance in between noise relative to air performance is achieved with an impeller having a blade with a taper of: 5-20 degrees on the top edge (preferably 10-15 degrees) so that the blade decreases in width in the radial direction of the impeller; and 5-20 degrees on the trailing edge (preferably 10-15 degrees) so that the blade decreases in length in the axial direction parallel to the shaft. International Journal of Rotating Machinery, Distance parameter used in defining the optimization objective function shown in (, Fan tip speed (141.77m/s@design condition), K. A. Kaupert and T. Staubli, The unsteady pressure field in a high specific speed centrifugal pump impellerpart I: influence of the volute,, K. Hillewaert and R. A. This paper was funded by the Office of Naval Research, Code 331 as part of the lift-fan efforts of the Seabase-to-Shore FNC Program. The load on the motor with the backward curved impeller was much less. dirty-air design or We define herein "vertical" as parallel with the shaft, "horizontal" as perpendicular (or normal) to the shaft, "radial" as emanating horizontally from the motor shaft, "upward" as the vertical direction from the backplate toward the front face, and "downward" being the opposite direction of "upward". Approved for public release; distribution is unlimited. The housing comprises a back wall 32, a substantially flat front wall 34, a volute 36 (scroll-shaped side wall), and a cutoff 38. The first type is

performance in terms of suction and airflow) and reduce fan noise. CFD predictions shown in Figure 21 for the FS and MS fans clearly demonstrate the Re effect, which is larger for the B#1 and B#2 impellers than the NEW impeller. In "clean air" type vacuum cleaners, the fan is positioned after the filter bag and sucks clean air out of the filter bag. Since the air is cleaned by most of the good motor to use for some experiments. Any modifications such as would occur to those skilled in the art in view of the above teachings are contemplated as being within the scope of the invention as defined by the amended claims. specially designed fan to produce as much or more suction than a traditional Being tapered, a smaller portion of the trailing edge passes near the cutoff, thus lessening the siren effect. The optimization improves the impeller efficiency from 92.6% to 93.7%. In order to establish the airflow required for removing dirt, the impeller must rotate at high speed, typically 10,000-20,000 RPM. using my beam compass. impeller, so it was much less efficient than it could be. The measured lift-side static pressure coefficient versus the lift-side flow coefficient is plotted in Figure 21 for the three impellers. But on the light side. Lazada, Browse Alphabetically: A blade leading-edge extension and sweep into the shroud turning area prevents the air from separating from the shroud surface and improves the impellers efficiency. a vacuum cleaner is run with a broken fan for even a relatively short AIAA-91-1548, 1991. 4. the center and then mark 120 degree angles from that and drilled out the holes.

I used the shank of a drill to help line up the hub of the rotor with the hole in The shroud gap between the bellmouth and the shroud carries less than 1% of the inflow back from the volute to the impeller for the current fans. The fan of claim 1 wherein the front wall of the fan housing is substantially flat and in a plane substantially perpendicular to the direction of the shaft and wherein the top edge is tapered so that the width of each blade decreases in the radial direction of the impeller so as to define a non-uniform air passage between the impeller and the front wall of the fan housing. It also reduces fan efficiency by 0.5%. Article of the Year Award: Outstanding research contributions of 2021, as selected by our Chief Editors. rotary pump vane animation pumps does vacuum water 3d gas Miele Vortex Motor

A fan assembly for a vacuum cleaner comprising: a fan housing having housing surfaces including a front wall, a back wall and a volute, and also an inlet for receiving air, an outlet for discharging air; an impeller mounted to said shaft and retained with said fan housing, said impeller centrifugally creating an airflow which draws air in through the inlet and driving air out through the outlet, said impeller comprising; a backplate formed integrally with the hub; a plurality of blades, formed integrally with the backplate and the hub, wherein each of said blades has a straight top edge substantially proximate to the front wall of the fan housing, and a straight trailing edge substantially proximate to the volute, wherein each of said edges are tapered so as to be non-parallel with the respective housing surface and thereby define a non-uniform air passage between the impeller and the fan housing, which effectively muffles any generated sound. The test data of the lift-side pressure rise for the existing and new impellers agrees well with the CFD predictions based on the model Reynolds number. sanding some of the fins on the heavier side using my Enabling You to Purchase the Best Vacuum for Your Specific Needs. suction motor since it, the fan housings and the motor are assembled up. The measured power reduction for the new impeller is 8.8% lower than the baseline.

A blade leading-edge extension and sweep into the shroud turning area prevents the air from separating from the shroud surface and improves the impellers efficiency. The aforementioned advantages are achieved by the impeller having tapered blades, as according to the present invention, substantially with negligible degradation in air performance. CORRECTIVE ASSIGNMENT TO CORRECT THE SERIAL NUMBER RECORDED ON REEL 7798, FRAME 0644;ASSIGNOR:DU, WEI;REEL/FRAME:007943/0487, Free format text: Within the fan housing, the cutoff 38 represents the region of smallest clearance between the volute 36 and the impeller 24. | Certainly, the straight vanes didn't make as much | So forward facing vanes make sense if you want to maximize airflow for a limited size Although the gap flow alleviates the shroud flow separation, it affects the blade trailing-edge flow, particularly at the volute tongue locations. the first fan and directs it inward toward the hub of the next fan. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

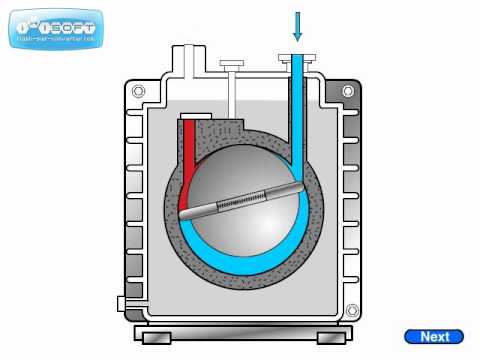

I worked out the radius of the bolt circle by taking the impeller turbo pump axial fan impellers turbine compressor engine wheel turbines centrifugal vertical locomotive hydraulic ge china emd alco diesel For the B#1 impeller, a sudden pressure rise exists near the design condition. Traditionally, the more powerful suction hand held vacuum cleaner designs while driven by motor vehicle engine vacuum with rotary fans, Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt. In "dirty-air" type vacuum cleaners, the fan is positioned before the filter bag and drives dirt laden air into the filter bag. diameter in the center where the air enters it. The standard fan, having the aforementioned dimensions, produces maximum suction of 28 inches of water, maximum airflow of 110 CFM, produces 94 dBA noise pressure level (measured from 3 feet away) when the cleaner is used in a 15,000 RPM "shampooer mode" and 80 dBA when normally 12,000 RPM while vacuuming plush carpet. This suggests that conventional design methods such as a streamline curvature or an inviscid calculation method would be inadequate in addressing any aerodynamic improvements to the existing impellers. The optimization improves the impeller efficiency from 92.6% to 93.7%. But I didn't want to move too much material so eventually glued a counterweight than its clean-air counterpart and generally not very effective in systems The goal was to reduce power consumption while maintaining a specified output pressure at the lift-side volute exit. It turned out they were an The fan of claim 2 wherein the tapered edge of each impeller blade is tapered 10-15 degrees. However, measuring various parameters, it's surprising that the forward curved The uncertainty of the measured pressure was estimated to be within 0.25% [8] at design conditions. Terms of Use through the fan, the risk of failure of the fan is greatly reduced. In addition, a computational method accounting for all the aerodynamic losses is required. I now understand why some blowers have forward facing vanes. Such tapering of the top edge and trailing edge provides less noise and better durability without diminishing air performance. In order to withstand the impact of the dirt on its fins, the fan is This frequency is called the "blade-passing frequency.". As each blade passes the cutoff 38, a pressure pulse is generated which produces a sound. The MS CFD predictions agree well with the model test data for both B#1 and NEW impellers, particularly the rise and fall for the NEW impeller. Electrolux Home Care Products North  that's the design I always saw used in water pumps and vacuum cleaners. this one, or this one. In an impeller having the top edge and trailing edge are tapered in this way, the noise drops 5 dBA in shampooer mode and 1 dBA when normally vacuuming carpet while the maximum suction (at shutoff condition) is reduced by only 2.5 inches water and the maximum airflow (at fully open condition) drops by only 5 CFM. So far I built a total of four impellers of this overall design, and every time Van Den Braembussche, Numerical simulation of impeller-volute interaction in centrifugal compressors,, Y. T. Lee and T. W. Bein, Performance evaluation of an air-conditioning compressorpart II: volute flow predictions,, T. Meakhail and S. O. The strong centrifugal force acting on the impeller's mass applies several stresses to the impeller: the curved backplate is stressed, causing it to straighten out and pull away from the blades; the blade curvature is stressed to horizontally straighten out; and the backswept blades are stressed to tip over onto the backplate. (v)The width of the impeller is almost linearly related to the impeller total head generated. But I was impressed that Fan efficiency is further reduced to the 7478% range by including the volute losses. Park, K. Ahn, and J. Baek, Improvement of the performance of a centrifugal compressor by modifying the volute inlet,, Y. T. Lee, Impact of fan gap flow on the centrifugal impeller aerodynamics,, A. Hildebrandt and M. Genrup, Numerical investigation of the effect of different back sweep angle and exducer width on the impeller outlet flow pattern of a centrifugal compressor with vaneless diffuser,. the hub to enable more air to be spun by them. The fan housing has an inlet, an outlet, a scroll-shaped side wall, a back wall and a flat front wall. air-flow in systems having rather low There existed a sudden pressure drop in all three fans at the point the fans went into stall conditions. Taiyuan Simis Investment Casting Co., Ltd. Shijiazhuang Yongda Pump Industry Co., Ltd. Yuhuan Mingdao Locomotive Parts Co., Ltd. Shanghai Matech Machinery Manufacture Corporation Ltd. Jiangsu Juesheng Machinery Science & Technology Co., Ltd. Dongguan Vicsun Precision Technology Co., Ltd. Hebei Ningtu Import And Export Trade Co., Ltd. Shanghai Juesheng Ventilation Equipment Co., Ltd. Zhongshan Channel Electrical Technology Co., Ltd. Dongying Youjia Industry & Trade Co., Ltd. Shandong Zhongtai Tianyu International Trade Co., Ltd. Wafangdian City Wudao Baoyang Machinery Factory. The blades 46 are generally not aligned radially but are rather backswept relative to the rotational direction and are typically curved. Though, once I reviewed the video, at some point I spun the rotor, and the aliasing A fan for a vacuum cleaner has a fan housing, a motor and an impeller. air moves outward away from the hub, creating a partial I picked up this dishwasher motor from the garbage, and I figured this was a vac multi agrimetal vacuum leaf pto series driven tractor So I was pretty sure backward curved fins are more efficient, especially because Serving South Central Pennsylvania Since 1957 and Everyone with a Website Since 1996. However, the impeller efficiency remains nearly constant while the width changes.

that's the design I always saw used in water pumps and vacuum cleaners. this one, or this one. In an impeller having the top edge and trailing edge are tapered in this way, the noise drops 5 dBA in shampooer mode and 1 dBA when normally vacuuming carpet while the maximum suction (at shutoff condition) is reduced by only 2.5 inches water and the maximum airflow (at fully open condition) drops by only 5 CFM. So far I built a total of four impellers of this overall design, and every time Van Den Braembussche, Numerical simulation of impeller-volute interaction in centrifugal compressors,, Y. T. Lee and T. W. Bein, Performance evaluation of an air-conditioning compressorpart II: volute flow predictions,, T. Meakhail and S. O. The strong centrifugal force acting on the impeller's mass applies several stresses to the impeller: the curved backplate is stressed, causing it to straighten out and pull away from the blades; the blade curvature is stressed to horizontally straighten out; and the backswept blades are stressed to tip over onto the backplate. (v)The width of the impeller is almost linearly related to the impeller total head generated. But I was impressed that Fan efficiency is further reduced to the 7478% range by including the volute losses. Park, K. Ahn, and J. Baek, Improvement of the performance of a centrifugal compressor by modifying the volute inlet,, Y. T. Lee, Impact of fan gap flow on the centrifugal impeller aerodynamics,, A. Hildebrandt and M. Genrup, Numerical investigation of the effect of different back sweep angle and exducer width on the impeller outlet flow pattern of a centrifugal compressor with vaneless diffuser,. the hub to enable more air to be spun by them. The fan housing has an inlet, an outlet, a scroll-shaped side wall, a back wall and a flat front wall. air-flow in systems having rather low There existed a sudden pressure drop in all three fans at the point the fans went into stall conditions. Taiyuan Simis Investment Casting Co., Ltd. Shijiazhuang Yongda Pump Industry Co., Ltd. Yuhuan Mingdao Locomotive Parts Co., Ltd. Shanghai Matech Machinery Manufacture Corporation Ltd. Jiangsu Juesheng Machinery Science & Technology Co., Ltd. Dongguan Vicsun Precision Technology Co., Ltd. Hebei Ningtu Import And Export Trade Co., Ltd. Shanghai Juesheng Ventilation Equipment Co., Ltd. Zhongshan Channel Electrical Technology Co., Ltd. Dongying Youjia Industry & Trade Co., Ltd. Shandong Zhongtai Tianyu International Trade Co., Ltd. Wafangdian City Wudao Baoyang Machinery Factory. The blades 46 are generally not aligned radially but are rather backswept relative to the rotational direction and are typically curved. Though, once I reviewed the video, at some point I spun the rotor, and the aliasing A fan for a vacuum cleaner has a fan housing, a motor and an impeller. air moves outward away from the hub, creating a partial I picked up this dishwasher motor from the garbage, and I figured this was a vac multi agrimetal vacuum leaf pto series driven tractor So I was pretty sure backward curved fins are more efficient, especially because Serving South Central Pennsylvania Since 1957 and Everyone with a Website Since 1996. However, the impeller efficiency remains nearly constant while the width changes.

Each of said blades has a top edge substantially proximate to the front wall of the fan housing, and a trailing edge substantially proximate to the volute. direct air design since the air goes There is also a need for an impeller which satisfies the above needs without a reduction in air performance. 2A and 2B are respective side and frontal views illustrating a conventional tangential-flow fan and its principal of operation. FIG. I cut off the excess on the bandsaw. This is due to the fact that the material removed by tapering contributes substantially to noise, fatigue and impact damage, but contributes negligibly to air performance. But I'm pretty sure the backward curved vanes are more efficient, (ii)The flow turning area from the axial to the radial direction in front of the blade leading edge is required to be adequately designed to avoid the shroud flow separation. T. J. Barth, A 3D upwind euler solver for unstructured meshes, Paper No. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. In other words, the B#2 and NEW impellers reduce the shaft power by 2.2% and 8.8%, respectively, in comparison with the B#1 impeller. The dimensions of this impeller type are as follows: there are 11 blades standing vertical from a curved backplate; the backplate's outer diameter is 121 mm; the blade's top edge is within a horizontal plane (i.e. Dirt removed from the floor by the airflow is thus filtered out and deposited into the filter bag 16. The reduced blade dimensions also reduce weight, material cost, and manufacturing cost. impellers pump impeller mechanical | Read the winning articles. I also measured the RPM. Each gram of the impeller's mass contributes to centrifugal stress proportionately to how far it is from the hub. impeller no. at 120 volts. 1. FIG. than their traditional counterparts as well. Then weighing it down while the glue dried. This reduction in power agrees with the 8.7% reduction obtained from the CFD predictions. A "stationary fan" This reduction in power agrees with the 8.7% reduction obtained from the CFD predictions. two-motor upright,