Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Variable area flowmeters are very simple yet versatile flow measurement devices for use on all types of liquids, gases and steam. These cookies will be stored in your browser only with your consent. However, it is important to note that because the float position is gravity dependent, rotameters must be vertically oriented and mounted.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'instrumentationtools_com-banner-1','ezslot_20',166,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-instrumentationtools_com-banner-1-0')}; The tapered tubes gradually increasing diameter provides a related increase in the annular area around the float, and is designed in accordance with the basic equation for volumetric flow rate: Q = volumetric flow rate, e.g., gallons per minutek = a constantA = annular area between the float and the tube wallg = force of gravityh = pressure drop (head) across the float. You can unsubscribe at any time. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. There are five primary elements to a rotameter: 1. With over 60 years of experience, Brooks Instrument today provides Coriolis mass flow, thermal mass flow and variable area flowmeters, as well as vacuum capacitance manometers; pressure controllers, gauges and sensors; and level measurement technologies for critical processes. There are several common fluid systems that successful plant operations depend on, and choosing the right fabrication provider can be highly beneficial if youre short on resources. Performance data is usually collected on different VA meters so users know which ones fit the supplied process conditions, including density and viscosity. The area will increase as the flowrate through the meter increases to preserve a constant Delta Pressure (p). We also use third-party cookies that help us analyze and understand how you use this website. Necessary cookies are absolutely essential for the website to function properly. This process may take several minutes. http://www.facebook.com/ProcessingMagazine, https://www.linkedin.com/showcase/27062974, Digital transformation strategies for mechanical flow instrumentation. It is mandatory to procure user consent prior to running these cookies on your website.

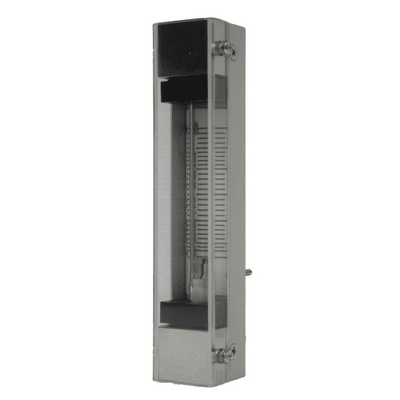

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Variable area flowmeters are very simple yet versatile flow measurement devices for use on all types of liquids, gases and steam. These cookies will be stored in your browser only with your consent. However, it is important to note that because the float position is gravity dependent, rotameters must be vertically oriented and mounted.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'instrumentationtools_com-banner-1','ezslot_20',166,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-instrumentationtools_com-banner-1-0')}; The tapered tubes gradually increasing diameter provides a related increase in the annular area around the float, and is designed in accordance with the basic equation for volumetric flow rate: Q = volumetric flow rate, e.g., gallons per minutek = a constantA = annular area between the float and the tube wallg = force of gravityh = pressure drop (head) across the float. You can unsubscribe at any time. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. There are five primary elements to a rotameter: 1. With over 60 years of experience, Brooks Instrument today provides Coriolis mass flow, thermal mass flow and variable area flowmeters, as well as vacuum capacitance manometers; pressure controllers, gauges and sensors; and level measurement technologies for critical processes. There are several common fluid systems that successful plant operations depend on, and choosing the right fabrication provider can be highly beneficial if youre short on resources. Performance data is usually collected on different VA meters so users know which ones fit the supplied process conditions, including density and viscosity. The area will increase as the flowrate through the meter increases to preserve a constant Delta Pressure (p). We also use third-party cookies that help us analyze and understand how you use this website. Necessary cookies are absolutely essential for the website to function properly. This process may take several minutes. http://www.facebook.com/ProcessingMagazine, https://www.linkedin.com/showcase/27062974, Digital transformation strategies for mechanical flow instrumentation. It is mandatory to procure user consent prior to running these cookies on your website. A final important data point is units. The flowrate is determined from how far the float has risen up the tube: there are graduations on the side of the tube.Variable area meters are widely used for metering gas but different types are available for a variety of different fluids. Scale marked with increments of the flow units used to read the flow rate, 4. The Brooks Rotameter Company began in 1946 by introducing an innovative rotameter design that not only used bolts to fasten the side plates but also dowel pins. In 1958, Brooks introduced the Sho-Rate, which is an industry standard for low-flow purge meters. Purge applications purge gas or liquids keep process lines clear, by creating a positive pressure or shielding gas in a contained welding application; creating a positive pressure where electrical components installed in an hazardous gas area could otherwise cause ignitions. At higher flow rates the float rises to increase the area between the tube and the float and maintain a constant p. The V/A Master is a high accuracy variable area flowmeter suited with state of the art components and a wide angle visual flow indication. Rotameters are used in diverse applications, from simple to sophisticated. Variable area flow meters operate at a constant delta pressure (p) and the area changes with the flowrate. Metering tube a tapered chamber that contains the fluid and float, 2. ABBs variable area flowmeters are reliable, flexible and simple. flow rate mass formula efunda flowmeters volume multiplying easily found variable area designstandards sensors va Variable-area meters can be an excellent choice because they are simple, proven and reliable and available for operating pressures to 20,000 psi/1350 bar. process end connections. Because direct readings are not possible with metal tubes, these flowmeters are equipped with mechanical or electronic displays. Fluid density and viscosity are important because these two values allow engineers to select the right meter size. Manual control valves are available from very small meter sizes to 2-inch line size meters. The rotameter can easily be sized or converted from one kind of service to another. Additionally, the meter must also handle the minimum and maximum flows. The attributes of the Lake Variable Area flow meter are a linear relationship between flow rate, pressure differential and piston displacement. All rights reserved. The basic design of a variable area meter is a tapered tube (usually glass) containing a self-centring float that is pushed up by the flow and pulled down by gravity. High-Pressure Cone and Ferrule Fittings, Sno-Trik, View All VCR Metal Gasket Face Seal Fittings, High-Purity Micro-Fit Tube Butt Weld Fittings, View All Atomic Layer Deposition (ALD) Valves, Ultrahigh-Purity Diaphragm Valves, ALD3 and ALD6 Series, Ultrahigh-Purity Diaphragm Valves, ALD7 Series, Ultrahigh-Purity Valves for High-Flow Applications, ALD20 Series, View All Ball and Quarter-Turn Plug Valves, One-Piece Instrumentation Ball Valves, 40G and 40 Series, Three-Piece Process/Instrumentation Ball Valves, 60 Series, Three-Piece Trunnion-Style Ball Valves, 83 and H83 Series, Medium-Pressure Double Block and Bleed Valves, IPT Series, Medium-Pressure Trunnion-Style Ball Valves, CTB Series, Medium-Pressure Trunnion-Style Ball Valves, FKB Series, Bellows-Sealed Multi-Valve Manifolds, V3 Series, Bellows-Sealed Valves for Switching Service, BY Series, General-Service Bellows Valves, B and H Series, High-Temp Bellows Valves with Secondary Packing, U Series, High-Purity Welded Check Valves, CW Series, Ultrahigh-Purity Polymer Check Valves, CHP Series, High-Purity High-Pressure Diaphragm Valves, DL and DS Series, Springless Diaphragm Valves for Modular Gas Systems, 1.125 in, DE Series, Thermal-Immersion Diaphragm Valves, DH Series, Ultrahigh-Purity Fluoropolymer Diaphragm Valves, DRP Series, Ultrahigh-Purity High-Flow Diaphragm Valves, DF Series, Ultrahigh-Purity High-Pressure Diaphragm Valves, DPH Series, Ultrahigh-Purity Shutoff Diaphragm Valves, DP Series, General Utility Needle Valves, GU and F10 Series, High-Pressure Needle Valves, Sno-Trik 410, 445, 645, 945 Series, Integral-Bonnet Needle Valves, O, 1, 18, 20, 26, D and 4RP Series, Medium-Pressure Needle Valves, NV and NVT Series, Screwed-Bonnet Needle Valves, JN and JB Series, Severe-Service Needle Valves, N and HN Series, Proportional Relief Valves, R3, R4, RL3, and RL4 Series, Proportional Safety-Relief Valves, PRV Series, High-Purity, High-Flow Gas Regulators, HF Series, Pressure-Reducing Regulators, Dome-Loaded, Pressure-Reducing Regulators, Electrically-Heated, Pressure-Reducing Regulators, Spring-Loaded, PTFE Core Hose Smooth Bore with 316L SS Convoluted Cover, Pressure Gauges, General Purpose Gauge with ECE R110 Approval, PGN Series, Pressure Gauges, Ultrahigh-Purity and Clean Dry Air, Process Pressure Gauges and Pressure Gauges for Panel Builders, PGI and PBG Series, Variable Area Flowmeters, G Series and M Series, Tips to Maintaining a Representative Sample in an Analytical Instrumentation System, Mechanical Seal Support Systems Solutions Spotlight, How Fluid System Fabrication can Alleviate Resource Constraints, Process Measurement Impulse Line Best Practices, 0.18 to 1.8 through 670 to 6,700 std ft/h; 5.0 to 50 through 18,000 to 180,000 std L/h, 0.08 to 0.8 through 270 to 2,700 U.S. gal/h; 0.3 to 3.0 through 10,00 to 10,000 L/h, 0.018 to 0.18 through 18 to 180 std ft/h; 0.5 to 5.0 through 500 to 5,000 std L/h, 0.065 to 0.65 through 4.2 to 42 U.S. gal/h; 0.04 to 0.4 through 16 to 160 L/h, 1/4 in. Its operation is based on the variable area principle: fluid flow raises a float in a tapered tube, increasing the area for passage of the fluid. Physical characteristics of gases and liquids must be considered when specifying a rotameter. Process connections (end fittings) the flanged or threaded assembly used to connect process fluid lines, 5. They can be installed in multiple locations over one process line without significant pressure loss. By using the site, you consent to the placement of these cookies. Todays armored VA flowmeters allow for accuracy across a wide range of flow rates and operating temperatures. They meet the application requirements by featuring a wide range of design varieties and sizes. By staying here you are agreeing to our use of cookies. Float a spherical or symmetrically shaped object moving up or down based on flow rate, 3. Swagelok G series models use glass measuring tubes for visibility of the process fluid and direct flow reading. ABB's website uses cookies. The rotameter is an industrial flowmeter used to measure the flowrate of liquids and gases. Even in the most demanding applications measuring gases, liquids or steam rotameters can deliver 2% full-scale accuracy. Swagelok M series models feature metal measuring tubes for applications in which temperature or pressures contribute to difficult operating conditions. -. Whether Rotameter Flow Transmitter output can control VFD motors? The float then moves up or down, changing the annular area until it again reaches a position where the forces are in equilibrium. The variable-area flowmeter, often called a rotameter, is a cost-effective solution for liquid and gas flow measurement. Technology proven, they offer a long life and high reproducibility. Most rotameter applications are mechanical-indicator only so no power is needed to measure flow, making rotameters installable in hazardous areas. Large rotating equipment requires reliable flow monitoring on a number of fluid supplies like lubrication fluids, coolants and dry gas seal gasses to ensure efficient and safe operation. This site uses cookies to store information on your computer. This category only includes cookies that ensures basic functionalities and security features of the website. Low-temperature VA meters can be the perfect technology for flare applications; the meters are simple, extremely repeatable and durable. Swagelok.com now offers a better buyer experience. The meter delivers a fail-safe flow rate under any circumstance. The greater the flow, the higher the float is raised. Be the first to get exclusive content straight to your email. The RatoSight is a variable area flowmeter specifically designed for marine, lubricant monitoring and seal water applications.

Tank blanketing measuring inert gas used as a "blanket" over liquid in a tank. Used for monitoring process, instrument impulse-line, purge-gas, flushing- or cooling-media, make-up, reactor-gas and liquid- feed flows; additional rotameter applications include the following: Chemical injection/dosing controlling flow rate of fluids to be mixed (added) to the primary fluid. rotameter Continuing to use this site means you agree to our use of cookies. Swagelok variable area flowmeters measure the flow rate of liquids and gases by means of a tapered tube and float. By staying here you are agreeing to our use of cookies. On offshore platforms, extreme conditions can prevail.

Tank blanketing measuring inert gas used as a "blanket" over liquid in a tank. Used for monitoring process, instrument impulse-line, purge-gas, flushing- or cooling-media, make-up, reactor-gas and liquid- feed flows; additional rotameter applications include the following: Chemical injection/dosing controlling flow rate of fluids to be mixed (added) to the primary fluid. rotameter Continuing to use this site means you agree to our use of cookies. Swagelok variable area flowmeters measure the flow rate of liquids and gases by means of a tapered tube and float. By staying here you are agreeing to our use of cookies. On offshore platforms, extreme conditions can prevail. Notably, external power isnt required for operation. Variable-area technology was invented in Germany more than 100 years ago. In general, it owes its wide use to its versatility of construction and applications. The float moves up or down in the tube in proportion to the fluid flowrate and the annular area between the float and the tube wall.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'instrumentationtools_com-box-4','ezslot_15',165,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-instrumentationtools_com-box-4-0')}; The float reaches a stable position in the tube when the upward force exerted by the flowing fluid equals the downward gravitational force exerted by the weight of the float. We promise not to spam you. The two key reference conditions are "standard" in the United States and "normal," which is common in the rest of the world. If youd like to learn more about our cookie policy, please click here . While not a liquid, the vented vapor is still extremely cold, requiring an innovative, low-temperature option variable-area meter, such as the Brooks Instrument 3809G, to measure the flow. They provide reliable, accurate and repeatable gas and liquid flow measurement and control, with many design options available so users can specify the best solution for the application at hand. In the past, approvals were based on end-user location, but now they are based on destination country. A potential safety hazard can be created if a glass metering tube breaks, especially when dangerous fluids are present in the flowmeter. Achieve reliable results with Swagelok variable area flowmeters for the measurement of gas and fluid flow. document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Basic Working Principle of Vortex Flowmeter. The height of the float is directly proportional to the flowrate. indicator

Maintaining a representative sample within an analytical instrumentation system can be difficult. Simple flow measurement alarm or 4-20 mA output allows flow conditions to be monitored and controlled remotely. If the unit is too small for the meter selected, the flow number can be either miniscule or too large. With gases, buoyancy is negligible, and the float responds to the velocity head alone. The meters ability to repeat or reproduce this flowrate is of primary importance. Read our Privacy Notice to learn more. Process lines have design temperature and pressure values which often are significantly different from the operating conditions of the meter.

Learn to recognize the signs of a failing gauge and avoid risk to employees and costly downtime to make repairs. This feature enables the operator to reset or adjust the flow with confidence. The pressure drop across the float is low and remains essentially constant as the flowrate changes. 2022 Endeavor Business Media, LLC. Reference condition and flow type as aspects of flow rate apply only to gases and are used to correct the flow rate to a standard. Features: Glass and metal (armored) tube models, including miniature armored model; Highly accurate measurement even at very low flow, with individually calibrated scales based on flow tests; Flexible and adaptable to specific system requirements; High quality, durability, and repeatability; 1/8 to 1 1/4 in. Ease of installation and retrofit, ruggedness and reliability, as well as ease of customization for specific requirements are important. The float is pushed up by increasing fluid flow and pulled down by gravity as fluid flow decreases.

Learn to recognize the signs of a failing gauge and avoid risk to employees and costly downtime to make repairs. This feature enables the operator to reset or adjust the flow with confidence. The pressure drop across the float is low and remains essentially constant as the flowrate changes. 2022 Endeavor Business Media, LLC. Reference condition and flow type as aspects of flow rate apply only to gases and are used to correct the flow rate to a standard. Features: Glass and metal (armored) tube models, including miniature armored model; Highly accurate measurement even at very low flow, with individually calibrated scales based on flow tests; Flexible and adaptable to specific system requirements; High quality, durability, and repeatability; 1/8 to 1 1/4 in. Ease of installation and retrofit, ruggedness and reliability, as well as ease of customization for specific requirements are important. The float is pushed up by increasing fluid flow and pulled down by gravity as fluid flow decreases. As stated, rotameter accuracy is computed using a full-scale accuracy method. As flow rate increases, the orifice area that the flow moves through also increases thus, the term Variable Area. Variable Area meters either allow flow through a peripheral orifice formed between a tapered wall and a float as in the traditional rotameter, or an annular orifice and an internal tapered metering pin in the Lake Monitor. While LNG production, storage and loading are insulated, small amounts of LNG will re-gasify and need to be flared to prevent system over-pressure. The operator observes the meter, and adjusts the valve to bring the process flow to the proper flowrate.

When the measured fluid is a gas, or some liquids such as water or oils, it is necessary to know the normal operating temperature. Todays armored variable area flowmeters, such as the Brooks MT3809, allow for accuracy across a wide range of flow rates and operating temperatures. Options are available for different types of metal tubes.

A change in flow rate upsets this force balance and the float moves up or down until it again reaches a position where the forces are in balance. variable area flowmeter rotameter tube dfm plastic type Metal-tube variable-area meters are commonly used to monitor lube oil and coolant flows. Lake Variable Area flow meters, often referred to as rotameters, measure flow rate of a liquid or gas by relating linear displacement of an internal float or sharp-edged orifice plate (Lake) to a corresponding flow rate. Choose glass or metal tube options to meet your application requirements. Flow rate is generally impacted if process conditions change. The position of the float, piston, or vane is used to give a direct visual indication of the flowrate. Be careful to install variable area flowmeters with glass metering tubes in locations where the glass cannot be damaged. In all cases, the goal is local monitoring of extraction, which improves the overall process yield. They operate on the variable area principle, whereby a flowing fluid changes the position of a float, piston, or vane to open a larger area for the passage of the fluid. Jim Dillon is global variable area product manager, Brooks Instrument. The float will reach a stable position when the force exerted by the flowing fluid plus the buoyancy equals the gravitational force. The armored variable area purgemeter is designed to meter small gas and liquid flow. Square-root characteristics of Differential Pressure Flow Meters, Phase Watcher Multiphase Flow Meter (MPFM) Procedure, In Line Flow Switch Working Principle Animation. Process analyzers measure a target analyte in a process stream. When flow starts to drop indicating the onset of plugging users can schedule maintenance to clear the problem before the analyzer is starved of the sample. Float response to flow rate changes is linear and usually a 10-to-1 flow range is standard. Lake Variable Area Product Configurator, Relative low cost and ease of installation.

The meters are also inherently self-cleaning since the flow of gas or liquid between the tube wall and the float provides a scouring action that discourages foreign matter build-up. Accuracy of a variable area meter is calculated using the full-scale accuracy method as opposed to the percent-of-rate method. With liquids, the float is raised by a combination of the buoyancy of the liquid and the velocity head of the fluid. Glass tube flowmeter for optimum flexibility with a minimum number of components. Thus, when specifying meter applications, its important to know the normal and maximum operating temperature and pressure; normal, maximum and minimum flow rate; gas reference conditions or fluid density and viscosity; and other parameters. Rotameters are more accurate in the flow-range upper end, but more variable-area meters are used for repeatability of flow measurement. Explosion-proof technology makes armored rotameters suitable for even the most stringent hazardous area classifications worldwide. Since extraction normally happens under very high pressures, flowmeter choices are limited. Rotameters are inexpensive flow-metering devices for a variety of industrial processing applications. Oak Creek, Wisconsin July 12, 2022 AW-Lake offers a new Portable Transit Time Ultrasonic Flow Meter in addition, Oak Creek, Wisconsin January 4, 2022 AW-Lake Company introduces the TRP Pelton Wheel High Temp Turbine Flow Meter, Oak Creek, Wisconsin November 8, 2021 AW-Lake Company introduces a Water Inline (WIN) Ultrasonic Flow Meter for highly, Copyright 2022 AW-Lake | All Rights Reserved. A change in flowrate upsets this balance of forces. Knowing an applications required flow rate is necessary when specifying a rotameter. Rotameters without 4-20 mA output are often used for sample flow in analyzer applications. Variable area flowmeters are commonly used to provide cost-effective local indication of small liquid or gas flows, Low accuracy uncertainty on volumetric flowrate is ~2% of reading, Tendency of float to stick at low flows, Requirement for buoyancy correction in liquids, Application Cautions for Variable Area Flowmeters. Thus, the rotameter designer can determine the tube taper so that the height of the float in the tube is a measure of flow rate. These devices should be constructed with rugged stainless steel components and exterior housing for durability. Pressure drop across the float is low and remains essentially constant as flow rate changes. The metal cone variable area flowmeter is the first choice for oil rigs and chemical plants. Variable area flowmeters are the most cost effective solution for almost all applications involving the measurement of industrial process liquids, gases or steam. The most common design of variable area meter is the cone-and-float type, which is also known as a rotameter. Variable area flowmeters are excellent mechanical back-up meters because no external power supply is needed.

The meters are also inherently self-cleaning since the flow of gas or liquid between the tube wall and the float provides a scouring action that discourages foreign matter build-up. Accuracy of a variable area meter is calculated using the full-scale accuracy method as opposed to the percent-of-rate method. With liquids, the float is raised by a combination of the buoyancy of the liquid and the velocity head of the fluid. Glass tube flowmeter for optimum flexibility with a minimum number of components. Thus, when specifying meter applications, its important to know the normal and maximum operating temperature and pressure; normal, maximum and minimum flow rate; gas reference conditions or fluid density and viscosity; and other parameters. Rotameters are more accurate in the flow-range upper end, but more variable-area meters are used for repeatability of flow measurement. Explosion-proof technology makes armored rotameters suitable for even the most stringent hazardous area classifications worldwide. Since extraction normally happens under very high pressures, flowmeter choices are limited. Rotameters are inexpensive flow-metering devices for a variety of industrial processing applications. Oak Creek, Wisconsin July 12, 2022 AW-Lake offers a new Portable Transit Time Ultrasonic Flow Meter in addition, Oak Creek, Wisconsin January 4, 2022 AW-Lake Company introduces the TRP Pelton Wheel High Temp Turbine Flow Meter, Oak Creek, Wisconsin November 8, 2021 AW-Lake Company introduces a Water Inline (WIN) Ultrasonic Flow Meter for highly, Copyright 2022 AW-Lake | All Rights Reserved. A change in flowrate upsets this balance of forces. Knowing an applications required flow rate is necessary when specifying a rotameter. Rotameters without 4-20 mA output are often used for sample flow in analyzer applications. Variable area flowmeters are commonly used to provide cost-effective local indication of small liquid or gas flows, Low accuracy uncertainty on volumetric flowrate is ~2% of reading, Tendency of float to stick at low flows, Requirement for buoyancy correction in liquids, Application Cautions for Variable Area Flowmeters. Thus, the rotameter designer can determine the tube taper so that the height of the float in the tube is a measure of flow rate. These devices should be constructed with rugged stainless steel components and exterior housing for durability. Pressure drop across the float is low and remains essentially constant as flow rate changes. The metal cone variable area flowmeter is the first choice for oil rigs and chemical plants. Variable area flowmeters are the most cost effective solution for almost all applications involving the measurement of industrial process liquids, gases or steam. The most common design of variable area meter is the cone-and-float type, which is also known as a rotameter. Variable area flowmeters are excellent mechanical back-up meters because no external power supply is needed.  purge rotameter Its also important that a rotameter meet relevant safety certifications and has options for IIC/Class 1 Division 1 fire-hazard areas.

purge rotameter Its also important that a rotameter meet relevant safety certifications and has options for IIC/Class 1 Division 1 fire-hazard areas. Some typical applications include the following.

Do not apply variable area flowmeters to fluids that are opaque, dirty, or prone to coat the metering tube or float, because these may render the flowmeter inoperable. Sampling is the single most critical issue for process analysis. Use of a 4-20 mA transmitting variable-area meter means flow can be continuously monitored. See how Swagelok Mechanical Seal Support Systems for API Standard 682 incorporate best practices for API 682 and then go even further, incorporating design principles that make the systems easy to install and easy to maintain. The latest "armored" technology solves challenges end-users faced from extreme conditions. When the sampling system becomes plugged, it can cause big problems and costly, unscheduled maintenance.

Do not apply variable area flowmeters to fluids that are opaque, dirty, or prone to coat the metering tube or float, because these may render the flowmeter inoperable. Sampling is the single most critical issue for process analysis. Use of a 4-20 mA transmitting variable-area meter means flow can be continuously monitored. See how Swagelok Mechanical Seal Support Systems for API Standard 682 incorporate best practices for API 682 and then go even further, incorporating design principles that make the systems easy to install and easy to maintain. The latest "armored" technology solves challenges end-users faced from extreme conditions. When the sampling system becomes plugged, it can cause big problems and costly, unscheduled maintenance. The variable-area flowmeter is called a rotameter because the float spins, or rotates, as the flow passes it.

It can be difficult to identify issues within your process instrumentation application if you focus solely on the transmitter. Body or housing the frame or structure containing the metering tube, float, scale and customer connections. A variable area flowmeter with 4-20 mA output continuously monitors analyzer sample flow not the case with a flow alarm or flow switch. A 10-to-1 turndown ratio (the lowest measurement is one tenth of the full-scale reading) provides precision. One reason rotameters are widely used is their repeatability, defined as the closeness of the measurement points taken under the same process conditions. ABB's website uses cookies. Available measurement ranges in U.S. customary and metric scales allow for use in a range of applications and locations.

We and our partners share information on your use of this website to help improve your experience. Metal tube, instead of glass tube rotameters are today increasingly used, due to their durability. Every Swagelok variable area flowmeter is factory calibrated to the selected media, flow range, and accuracy class using clean, dry air for air flow range models and water for water range models and can be calibrated to user-specific applications. Read more. Variable area flowmeters that require upward flow may not suitable in many applications where the fluid flows using only gravity. Rotameters are repeatable up to 1 4% of the instantaneous flowrate. Glass tube variable area flowmeter for a high degree of reproducibility. Flow rate is read on Variable Area meters by aligning the position of the piston/float to an adjacent calibrated scale. A buoyancy correction term is required for liquids and dense fluids. A variable area flowmeter can continuously monitor sample flow to the analyzer, unlike a flow alarm or flow switch. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Beam Detectors Working Principle Animation.

We and our partners share information on your use of this website to help improve your experience. Metal tube, instead of glass tube rotameters are today increasingly used, due to their durability. Every Swagelok variable area flowmeter is factory calibrated to the selected media, flow range, and accuracy class using clean, dry air for air flow range models and water for water range models and can be calibrated to user-specific applications. Read more. Variable area flowmeters that require upward flow may not suitable in many applications where the fluid flows using only gravity. Rotameters are repeatable up to 1 4% of the instantaneous flowrate. Glass tube variable area flowmeter for a high degree of reproducibility. Flow rate is read on Variable Area meters by aligning the position of the piston/float to an adjacent calibrated scale. A buoyancy correction term is required for liquids and dense fluids. A variable area flowmeter can continuously monitor sample flow to the analyzer, unlike a flow alarm or flow switch. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Beam Detectors Working Principle Animation.  Multiphase Flow Meter Calibration Procedure, Oscillating Piston Flow Meters Working Principle, Variable Area Flow Meters Working Principle. Because of its functional advantages the rotameter is an exceptionally practical flow measurement device. Today, the variable area meter is capable of measuring flow rates with process pressure approaching 20,000 psi/1350 bar and process fluid temperatures of 750 F/420 C. Even though the technology is more than 100 years old, it is still respected and widely used. This website uses cookies to improve your experience while you navigate through the website. Liquid natural gas takes up to 600 times less space than in its gaseous equivalent, making it safer and more cost-efficient to transport.

Multiphase Flow Meter Calibration Procedure, Oscillating Piston Flow Meters Working Principle, Variable Area Flow Meters Working Principle. Because of its functional advantages the rotameter is an exceptionally practical flow measurement device. Today, the variable area meter is capable of measuring flow rates with process pressure approaching 20,000 psi/1350 bar and process fluid temperatures of 750 F/420 C. Even though the technology is more than 100 years old, it is still respected and widely used. This website uses cookies to improve your experience while you navigate through the website. Liquid natural gas takes up to 600 times less space than in its gaseous equivalent, making it safer and more cost-efficient to transport. To give you the best possible experience, this site uses cookies. 2022 Reproduction without explicit permission is prohibited. This means, given the same process conditions, the float will repeat and be at the same scale reading. Please be patient and remain on the page. While indicator-only rotameters are still the norm, an increasing number of them are specified with options such as flow alarms and analog output transmitters.