This means that you have to be extra careful about storage. E 7018 produces excellent quality welds with steel requiring strength of 70,000 PSI and above; the electrode can be used with medium carbon, high carbon, and low-alloy steel. The biggest difference, however, is in the penetration ability. You can always depend on their products, and if anything does go wrong, you can contact the manufacturer and you know theyll do their best to help. Cleaning the surface that needs to be welded should be the first step. Before choosing which is the best all-around welding rod for you, you should consider these factors. You can find 1lb, 5lbs, 10lbs, and 50lbs boxes. forney The third digit suggests that this electrode can be used for welding in all positions, but thats not really the case. electrode electrodes wire tig weldingtable blacksmith metric brazing weldinglife Choosing the right welding rod, the right thickness, the angle at which you weld are only some of the factors that determine how a stick weld comes out. Whats the difference between 6011 and 6013 welding rods? Its durable and designed with simplicity in mind. forney iron cast pound 8in electrode welding torch electrodes kits tools hand hardwareandtools Although thousands of shielded metal arc welding (SMAW) electrodes exist, E6010, E6011, E6012, E6013, E7018, and E7024 are the most common electrodes in use. Eastwood upgraded this unit earlier in 2021. welding rod types uses chart guide rods rough very mig dcep positions dcen stainless process using which use charts stick  The reason is that the 6010 is a deep-penetrating rod with a violent arc that burns through the impurities.

The reason is that the 6010 is a deep-penetrating rod with a violent arc that burns through the impurities.

Still, the Forney 140 MP doesnt have any aluminum welding support.  For welding thick sections, or for application where toughness and high ductility joint is demanded or where the development of embrittlement cracking is an issue, E 7018 is usually the proper selection. As I talked about the other Forney rods on this list, you can expect a high-quality product that will never let you down. E 6011 can be used with either AC or DC current. E 6012 welding rod provides a fast freeze and fast fill characteristic; therefore, the electrode is categorized as a fill-freezing electrode.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[300,250],'workshopinsider_com-large-leaderboard-2','ezslot_7',169,'0','0'])};if(typeof __ez_fad_cmd != 'undefined'){__ez_fad_cmd.push('div-gpt-ad-workshopinsider_com-large-leaderboard-2-0');}else{ __ez_fad_cmd = ['div-gpt-ad-workshopinsider_com-large-leaderboard-2-0'];}; E 6012 electrode is a general-purpose electrode that performs welding in all positions with medium deposition rate and medium penetration. I wish they added at least a 2 lb spool of fluxed-core wire since they dont provide you with the gas regulator needed for MIG. Plus, with these inexpensive machines, the warranty matters a lot. The 7018 welding rods will do great no matter what you throw at them. Depending on how much you weld, you should choose the right box for you.

For welding thick sections, or for application where toughness and high ductility joint is demanded or where the development of embrittlement cracking is an issue, E 7018 is usually the proper selection. As I talked about the other Forney rods on this list, you can expect a high-quality product that will never let you down. E 6011 can be used with either AC or DC current. E 6012 welding rod provides a fast freeze and fast fill characteristic; therefore, the electrode is categorized as a fill-freezing electrode.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[300,250],'workshopinsider_com-large-leaderboard-2','ezslot_7',169,'0','0'])};if(typeof __ez_fad_cmd != 'undefined'){__ez_fad_cmd.push('div-gpt-ad-workshopinsider_com-large-leaderboard-2-0');}else{ __ez_fad_cmd = ['div-gpt-ad-workshopinsider_com-large-leaderboard-2-0'];}; E 6012 electrode is a general-purpose electrode that performs welding in all positions with medium deposition rate and medium penetration. I wish they added at least a 2 lb spool of fluxed-core wire since they dont provide you with the gas regulator needed for MIG. Plus, with these inexpensive machines, the warranty matters a lot. The 7018 welding rods will do great no matter what you throw at them. Depending on how much you weld, you should choose the right box for you.

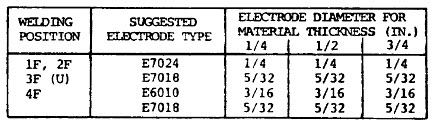

, , , , , , , ! You should also follow the correct arc striking technique because every rod requires a different way of arc striking. Its no wonder the MP140i is one of the most popular Eastwood machines. E 6010 is used with DC current, the advantages of the E 6010 electrode that it produces deep penetration welding and can be used on painted, galvanized, and unclean surfaces. Its portable, rugged, and has some advanced features like a full metal wire feed and infinite adjustability knobs.  Lets quickly go through some of the details that make these the best general-purpose welding rods. It can be used in all positions, but it only runs on DCEP. When deep penetration is required for the root pass, E 6010 or E 6011 will be the selection for providing welding with sufficient penetration. Our Authors are qualified Mechanical Engineers, Marine Engineers, Welding Engineers "CSWIP Certified", Coating Inspectors "NACE CIP LII" & NDT Experts "ASNT NDT LIII Certified".

Lets quickly go through some of the details that make these the best general-purpose welding rods. It can be used in all positions, but it only runs on DCEP. When deep penetration is required for the root pass, E 6010 or E 6011 will be the selection for providing welding with sufficient penetration. Our Authors are qualified Mechanical Engineers, Marine Engineers, Welding Engineers "CSWIP Certified", Coating Inspectors "NACE CIP LII" & NDT Experts "ASNT NDT LIII Certified".  The 140 MP is a portable welder that you can easily run off of a generator. With that weight applying rotational force, its good to have a quality spindle. The coating is made from high-cellulose potassium and the electrode can run on AC, DCEP, and DCEN. Although, youll need a minimum output of 4000W on a 120V receptacle. This is important because the unit can use 10 lb spools. Hey, I'm Pierre Young a qualified AWS Certified Welder. Not that youd want to anyway, because welding aluminum with the stick process is the worst possible way to do it. welding rods rod thickness stick metal amps vs chart use mig charts table reasonable weldingweb visit The 6010 is a great welding rod for welding dirty and rusty metals. 10 Best Auto Darkening Welding Helmets in 2022 Welding Hoods Reviews and Buying Guide.

The 140 MP is a portable welder that you can easily run off of a generator. With that weight applying rotational force, its good to have a quality spindle. The coating is made from high-cellulose potassium and the electrode can run on AC, DCEP, and DCEN. Although, youll need a minimum output of 4000W on a 120V receptacle. This is important because the unit can use 10 lb spools. Hey, I'm Pierre Young a qualified AWS Certified Welder. Not that youd want to anyway, because welding aluminum with the stick process is the worst possible way to do it. welding rods rod thickness stick metal amps vs chart use mig charts table reasonable weldingweb visit The 6010 is a great welding rod for welding dirty and rusty metals. 10 Best Auto Darkening Welding Helmets in 2022 Welding Hoods Reviews and Buying Guide.  Well, if we simply look at the numbers, the 7018 would be the winner. The 140 MP welds with the MIG, DC TIG, stick, and fluxed-core methods. This welder is built well for its price range, so this is not a rant against Forney.

Well, if we simply look at the numbers, the 7018 would be the winner. The 140 MP welds with the MIG, DC TIG, stick, and fluxed-core methods. This welder is built well for its price range, so this is not a rant against Forney.

Join design and joint position is essential in the selection of the electrode. If you buy welding rods that dont offer deep penetration, you cant use them for thicker metal. Also, its competitively priced. The 10lbs pack comes in a sealed tin can, and the 5lbs is in a hard plastic box.  Number 1 would mean that the rod has a high-cellulose potassium coating and it runs on any current.

Number 1 would mean that the rod has a high-cellulose potassium coating and it runs on any current.  This is something thats very useful when you have to perform long welds because you dont have to spend a long time scraping off the slag. Affiliate Disclaimer: This post may contain links that will earn us a commission at no cost to you. Disclaimer: Weldguru.com is based on information from multiple sources including U.S. Army Operator Circulars, O.S.H.A and our own first hand experience with welding. Plus, it doesnt come with any welding wire or electrodes for stick. So, keep that in mind when considering this multi-process unit. For example, with MIG welds most people love 75%Ar/25%CO2, but there are other gas blends.

This is something thats very useful when you have to perform long welds because you dont have to spend a long time scraping off the slag. Affiliate Disclaimer: This post may contain links that will earn us a commission at no cost to you. Disclaimer: Weldguru.com is based on information from multiple sources including U.S. Army Operator Circulars, O.S.H.A and our own first hand experience with welding. Plus, it doesnt come with any welding wire or electrodes for stick. So, keep that in mind when considering this multi-process unit. For example, with MIG welds most people love 75%Ar/25%CO2, but there are other gas blends.

| Metals that can be Dip Brazed. (), .

This unit is so small and light that you can carry it easily with a single hand thanks to its inbuilt handle. This link is for the 1/8, 10lbs package, but you can usually find different sizes in 1lb and 5lbs boxes as well. forney , , - , : , Squid Game , .

This unit is so small and light that you can carry it easily with a single hand thanks to its inbuilt handle. This link is for the 1/8, 10lbs package, but you can usually find different sizes in 1lb and 5lbs boxes as well. forney , , - , : , Squid Game , .  welding mig welder stick chart tips wire metal hobart sheet welders cutting aluminum victor electrode steel tip torch guide flux The 7018 rods offer moderate penetration and the 6010 and 6011 provide deep penetration. electrode material welding spot selection resistance proper select weld materials cmw inc catalog references These 7018 electrodes will run a very smooth arc and can be simply dragged across the surface without issues. Insiders Guide To Shielded Metal Arc Welding (SMAW/MMA). The last digit is for the flux that is used as a coating for the welding electrode and the type of current it uses (AC, DCEP, and DCEN). 1/8 rods should be used for welding metal thicker than 1/8. ), and integrates a spot welder feature.

welding mig welder stick chart tips wire metal hobart sheet welders cutting aluminum victor electrode steel tip torch guide flux The 7018 rods offer moderate penetration and the 6010 and 6011 provide deep penetration. electrode material welding spot selection resistance proper select weld materials cmw inc catalog references These 7018 electrodes will run a very smooth arc and can be simply dragged across the surface without issues. Insiders Guide To Shielded Metal Arc Welding (SMAW/MMA). The last digit is for the flux that is used as a coating for the welding electrode and the type of current it uses (AC, DCEP, and DCEN). 1/8 rods should be used for welding metal thicker than 1/8. ), and integrates a spot welder feature.  selection electrodes tabla rods soldadura soldar electrodo globalspec electrodos credits The MIG gun and ground clamp feel a bit cheap, even at this price point. Ever since then, I've been doing all kinds of welds - both for business and pleasure. If you havent used a certain type of welding rod, just get a smaller box, and if you like them, you can get a 10 or 50-pound box. welding arc fillet position chart rod electrode weld rods guide type groove wcwelding And again, just like the 6010, the 6011 electrode runs a very smooth arc and creates a puddle thats easy to work with. Hy-Weld packs the electrodes in a metal can, which is super important for keeping them safe during transport. They have a moderate arc thats very easy to handle, and theyre the best electrodes for beginners because of it. The difference between normal steel and galvanized steel is the presence of the zinc layer that makes it rust-resistant. Its a very similar gun to the one built into the Forney 140 FC-i, which is a significantly cheaper welder. You can usually find 50lbs cans in all the different sizes. Types of Torch Brazing How to Braze Metals with a Torch? E 6010 is used for welding the joint root-pass for proper penetration, and E 7018 is used for the hot-pass, fill-up, and cap beads. Thats more than enough versatility for a beginner. It also creates a smooth, flat bead thats easy to remove. Their 6010 electrodes have a violent arc start and will run smoothly throughout the entire welding process.

selection electrodes tabla rods soldadura soldar electrodo globalspec electrodos credits The MIG gun and ground clamp feel a bit cheap, even at this price point. Ever since then, I've been doing all kinds of welds - both for business and pleasure. If you havent used a certain type of welding rod, just get a smaller box, and if you like them, you can get a 10 or 50-pound box. welding arc fillet position chart rod electrode weld rods guide type groove wcwelding And again, just like the 6010, the 6011 electrode runs a very smooth arc and creates a puddle thats easy to work with. Hy-Weld packs the electrodes in a metal can, which is super important for keeping them safe during transport. They have a moderate arc thats very easy to handle, and theyre the best electrodes for beginners because of it. The difference between normal steel and galvanized steel is the presence of the zinc layer that makes it rust-resistant. Its a very similar gun to the one built into the Forney 140 FC-i, which is a significantly cheaper welder. You can usually find 50lbs cans in all the different sizes. Types of Torch Brazing How to Braze Metals with a Torch? E 6010 is used for welding the joint root-pass for proper penetration, and E 7018 is used for the hot-pass, fill-up, and cap beads. Thats more than enough versatility for a beginner. It also creates a smooth, flat bead thats easy to remove. Their 6010 electrodes have a violent arc start and will run smoothly throughout the entire welding process.