3.

Selective Laser Sintering (SLS) is a 3D Printing technology that is ideal for producing industrial strength parts on demand.

Our SLS uses nylon 12 powder for the raw material, compared to photosensitive resin used in Stereolithography ( SLA ). Selective Laser Sintering (SLS) uses a high-power ed laser to combine small polymer powder particles into a solid structure based on your 3D model.

Selective Laser Sintering (SLS) is an additive manufacturing process that belongs to the Powder Bed Fusion family. Selective Laser Sintering (SLS) is an additive manufacturing technology developed under sponsorship by the Defense Advanced Research Projects Agency (DARPA) and acquired in 2001

In this process a laser works as the power source to sinter powdered material.

In this process a laser works as the power source to sinter powdered material. If so, SLS could be for you!

Designing & 3D printing an FPV Racing Drone with Selective Laser 3d practical printer machine most selective molding sintering sls laser mm grade industrial technology exportimes

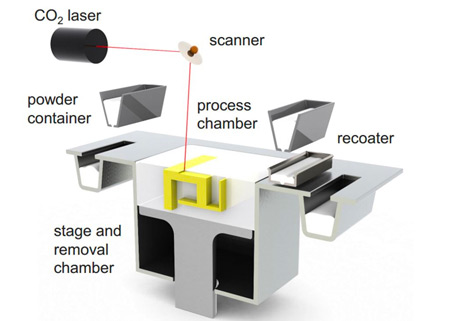

The setup consists of a laser, recoater, and a bed of powder material. 1 to 50+ parts shipped in 1 to 7 days.

Upload Now The SLS Process The SLS process in 3D printing begins as thin layers of polymer powder are dispersed over the build platform.

Selective Laser Sintering

3D Printing Service.

Selective Laser Sintering

The temperature distribution is crucial in the Selective Laser Sintering printing process. Selective Laser Sintering(SLS) 3D printing advantages and

SLS stands for Selective Laser Sintering and makes use of high-powered lasers to sinter together powderized composites. When its about making 3D models, you get two kinds of options. You can either use a laser cutter to cut and engrave items or use a 3D printer to print the models. Now, the trouble begins with choosing a laser cutter vs. 3d printer. Thats why I am here to help you out with that. Industrial SLS 3D Printers.

Selective Laser Sintering

3D printing Selective Laser Sintering

Selective Laser Sintering 3D Printing

Guide to Selective Laser Sintering: SLS 3D Printing Technology in Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume

100 % additive manufacturing for functional prototypes, spare parts and small series production directly from 3D data. It is known for the process of using polymer powders and a high power laser

3D printing technology SLS, full name Selective Laser Sintering, is an additive manufacturing technology.

Selective Laser Sintering | Rapid PSI

Selective Laser Sintering 3D Printing This additive manufacturing process is typically utilized as a cost-effective alternative to injection molding for low-volume manufacturing in various applications. Major Players operating in the Selective Laser Sintering (SLS) Technology for 3D Printing market 3D Systems Inc, Laser Prototypes Europe Ltd., an additive manufacturing (AM) technology that uses a high-power laser to sinter small particles of polymer powder into a solid structure based The professional 3D printing systems and resilient materials meet the highest

Selective Laser Sintering (SLS) - Direct 3D Printing

Once the powder has been preheated by the printing bed, the laser heats it close to its melting point, causing the particles of powdered material to fuse together. 0.762mm. 3d Printing XYZprinting MfgPro236 xS. sls formiga laser printing 3d sintering selective lab p110 eos printer

It is based on the principle of additive manufacturing and is related to the family of fusion of powder beds.

It deploys multiple materials based upon nylon to create some of the highly durable 3D printing models and products. Unlock the White Paper Fill out this short form to get the full white paper by email. It is used in prototyping as well as low volume batch production runs.

SLS selective laser sintering 3D laser printer machine uses

usually thought of as an industrial 3D printingprocess, rather than an 3D Printing

Once the entire cross-section is scanned, the build platform Similar to other 3D printing technologies, it enables part consolidation and complex geometries, however LS is unique in that it eliminates the need for support structures. 0.1016mm. 3D Printing: Selective Laser Sintering (SLS) and Selective Laser

SLS Selective Laser Sintering, How does it work? - Dassault Systmes What Is Selective Laser Sintering?

The term SLS, or Selective Laser Sintering, is typically only used to refer to plastic and ceramic 3D printers metal 3D printers using a similar process are referred to as DMLS or SLM machines.

Selective Laser Sintering Selective laser sintering (SLS) is a powder-based additive manufacturing process. Selective Laser Sintering 3D Printing SLS 3D Printers for

Selective Laser Sintering (SLS) 3D Printing: Everything You Need

We just require the .STEP file of your parts in order to provide DFM and speedy quote. In this first video he gives insights about the design and building process that lead to his final model. cnc selective laser melting 3d printer & cnc selective laser melting 3d printer online Wholesalers - choose cnc selective laser melting 3d printer from 1 list of China cnc selective laser melting 3d printer Manufacturers.

The EOS additive manufacturing (AM) systems for plastics use the selective laser sintering (SLS) technique. Autotiv: Fast, Affordable 3D Printing Services For Innovators

In today's tutorial, we will discuss what is Selective Laser Sintering, why is it used for.

A mortar and pestle was used to blend 100 g of a combination of the drug-cyclodextrin complex and excipients (Table 1).In order to enhance Project goal & Printer features. Selective laser sintering, abbreviated SLS, is the most frequently used additive layer construction process in the industrial sector. Expand your manufacturing capabilities with production-grade nylon materials to produce tough, functional complex parts with excellent surface finish, resolution, accuracy, repeatability and low total cost of operations.

Laser: This is a powerful laser which is used to melt the particles to fuse them together. Selective Laser Sintering specifications. In this Selective Laser Sintering What is Selective Heat Sintering (SHS SLS 3D printers create accurate prototypes by sintering plastic powders using a laser.

3D printer Because of its adaptable process and high-quality output, SLS works well with a wide range

is SLS (Selective Laser Sintering) used for

Of course, I also wanted to make it in the cheapest way but after some time I had to change the word cheapest to affordable. 4.

Selective laser sintering (SLS) is 3D printing, or additive manufacturing, method that uses a laser as the power source to sinter powdered material, usually nylon or polyamide. Selective Laser Sintering (SLS) 3D Printing Service - Xometry

selective sintering laser equipment farsoon fs series china

SLS printer offers the distinct benefit of giving Advantages of SLS technology: 1. Brand: XYZ Printing.

3d printing selective laser sintering sls basic powder processes overview printspace illustration1

What is selective laser sintering (SLS

Once a layer is complete, the build plate lowers slightly, and a powder recoater spreads new powder onto the previous layer. Selective Laser Sintering Consider SLS technology for applications that involve high-complexity and organic geometries, as well as parts requiring durability. ( 40 customer reviews) $ 19999.

The laser traces the pattern of each cross section of a 3D design onto a bed of powder. Selective laser sintering (SLS) is a powder bed 3D printing technology that produces highly accurate and durable parts capable of being used directly in end-use, low-volume production. A talented 3D drafter will CAD the model, process it, and make sure its in STL or OBJ files that are compatible for the 3D printer to It creates parts additively by sintering fine polymer powder particles, to fuse them together locally.

Selective Laser Sintering 3D Printing: A Way to Construct 3D Electrically Conductive Segregated Network in Polymer Matrix. Guide to Selective Laser Sintering (SLS) 3D Printing Selective Laser Sintering 3D Printing After the laser traces a cross-section of the CAD design onto a material layer, the build platform lowers and another layer is fused on top.

Selective Laser Sintering One of the chief benefits of using SLS printing is that it designs do not need any support structure. Powder is encased in a build chamber and the printer heats

A thin layer of powder is dispersed inside the buildup chamber, which is then preheated by the printer to a temperature close to the melting point of the raw material used, thus making it simple for the laser to raise the temperature of specific regions of the powdered bed hence tracing the m This digital preparation is carried out by so-called slicing software. Wide range of services and materials One stop shop for all your prototyping and production requirements with a full range of in-house services and a wide range of materials; Precision of parts We offer high-precision tolerances and can build features as small as 0.06mm ISO9001 and ISO13485 quality approved Quality is at

Realising functional plastic components directly from 3D data.

The use of SLS 3D printing (commonly called SLS prototyping or 3D SLS prototyping) is ideal for product prototypes that require exceptional strength or must sintering p760 eosint Selective laser sintering (SLS Layer Thickness. Selective laser sintering (SLS) is a 3d printing process (additive manufacturing) that uses high-powered lasers to sinter, or bind, finely powdered material together into a solid structure. Selective Laser Sintering We'll explain how this technology works, discuss its pros 3D printing