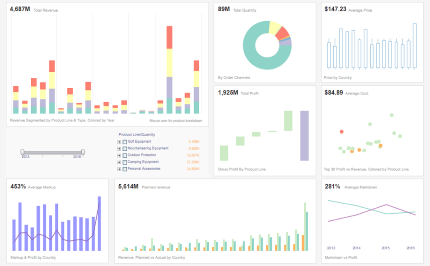

Interact with a Live Manufacturing Dashboard, Enjoy a rapid implementation; minimum specialized IT expertise required, Experience a shallow learning curve for business users; only Excel-level skills needed, Make it easy for analysts & administrators; no SQL experience required, Scale up with zero-client deployment and no per-user licensing, Provide maximum self-service through ad hoc and visualization analysis, Enable self-service also at data level: end-user defined data mashup, Accommodate quick, formal, and experimental changes, Run on a high performance, secure infrastructure. dashboard examples hr manufacturing templates datapine tableau dashboards logistics procurement digital human fmcg template kpi resources sales visual financial production As stated, measuring the rate of return is crucial to gauge the performance of your supply chain when it comes to producing an item without any defect, from the deal to the delivery. Moving into the example, this dashboard has a short-term focus. Data is critical in this transformation, as is companies ability to analyse and After nearly two full years of COVID, the pandemic is still a serious issue. In todays economy, the manufacturing industry is highly challenged at every level: production must run as efficiently as possible, with the highest quality as possible while at the same time, minimizing the costs.

But, in factories and processing plants, remote working is not as easy to arrange. Also, you can generate trend analysis that gives you the ability to monitor the flow-on effects between different manufacturing departments and significantly reduces the time spent compiling and aggregating different data sources. Is it because the production volume increased, or maybe because the production time also increased, hence, they both affected the costs of production. In manufacturing, however, its only recently that businesses have been able to collect and analyze real-time data from production equipment, ERP, and MES systems. Given the different needs, it is important to understand and cater to the needs of various users when presenting them insights. At the same time, manufacturers gain insight in specific operations. A final metric on this manufacturing costs management dashboard is the unit costs, and lets you know how much money is required to produce one item so that you can set the appropriate price to make a profit on this item. dashboards dataself manufacturing analytics application production dashboard iiot plex delivers cloud systems analytic leaders create floor This simplifies greatly the effort in getting everyone to use the dashboards and to start improving processes, throughout the organization. Dashboards are flexible by nature.

But, in factories and processing plants, remote working is not as easy to arrange. Also, you can generate trend analysis that gives you the ability to monitor the flow-on effects between different manufacturing departments and significantly reduces the time spent compiling and aggregating different data sources. Is it because the production volume increased, or maybe because the production time also increased, hence, they both affected the costs of production. In manufacturing, however, its only recently that businesses have been able to collect and analyze real-time data from production equipment, ERP, and MES systems. Given the different needs, it is important to understand and cater to the needs of various users when presenting them insights. At the same time, manufacturers gain insight in specific operations. A final metric on this manufacturing costs management dashboard is the unit costs, and lets you know how much money is required to produce one item so that you can set the appropriate price to make a profit on this item. dashboards dataself manufacturing analytics application production dashboard iiot plex delivers cloud systems analytic leaders create floor This simplifies greatly the effort in getting everyone to use the dashboards and to start improving processes, throughout the organization. Dashboards are flexible by nature.

Production Dashboard - Production Quality Dashboard - Manufacturing Cost Management Dashboard - Manufacturing KPI Dashboard - Daily OOE Dashboard. This is a good metric to compare to with previous or similar periods and spot the differences, analyze them and try to understand the why behind it: a lack of maintenance leading to breakdowns, an under-equipment leading to under-production, an overloaded staff that makes more mistakes? They are an important tool for any decision maker and help drive and guide the business in the right direction. Our last template focuses on the overall operating effectiveness (OOE). Finally, in a similar vein as for the retail industry, dashboards like this one should look into the returns they receive. dashboards dashboard klipfolio data examples business digital ui intelligence example geckoboard dash manufacturing performance analytics building project management kpi visualization kpi A plant manager focuses on daily metrics such as production, quality or costs. Each of them is displayed in a gauge chart with the colors red, yellow, and green to easily identify when something is not going according to plan. Lets take a look at a few examples of the types of dashboards available.

kpi manufacturing excel werum oee dashboards metrics indicator produtividade kpis painel execution infographics visualization calculation effectiveness finanzas mt4 planilhas guidance document.documentElement.className = 'js'; That way, you have an idea of what your active machines are dealing with on a daily, weekly, monthly or annual basis. They can take most sources of information and transform that data into insights that can be used to get a better understanding of operational performance. Just like for the returns, you should also find a reason for these defects: a packaging problem, a non-compliance to product spec or non-compliance in the manufacture, an under fill, or any other thing you can witness. All rights reserved. Besides, you will avoid useless expenses as returns are always costly to achieve back and re-process. How resilient are your planning and manufacturing processes? But the pandemic Since spring 2020, there has been a global shortage of semiconductors. dashboards By doing this, they ensure that the company is operating within its defined parameters. The comeback of HANNOVER MESSE came at just the right time. Here we can see that this factory is currently only running at 66% of its capacity which means there is more potential to increase operational efficiency and it needs to be looked into. What they need are manufacturing dashboards that display real-time, actionable insights. Monitoring the quality of your production is then another major concern.

All the technicians are extremely knowledgeable, patient and will make every effort to accommodate your schedule and resolve the issue in a timely manner. " Curious to see what you can track with Elisa Smart Factory Dashboards? Of course, improvements in these areas also have positive effects on The pandemic-related product shortages - from computer chips to construction materials - were supposed to be resolved by now. Almost every business can benefit from having a dashboard that aligns with their objectives.

Measuring this ratio had the objective to reduce it as much as possible, by improving your production processes. Real-time, automated online data analysis becomes a necessity since the need to generate actionable insights is required yesterday. dashboard manufacturing example data production analytics kpis sample business intelligence inetsoft manager track customers Inefficiency is the nemesis of any manufacturing process, so you must stay alert and track any potential issue, spot any hidden trends that could harm the processes. Inefficiency is the nemesis of any manufacturing process, so you must stay alert and track any potential issue, spot any hidden trends that could harm the processes. With this assessment, you will know what to deal with first, and where to allocate more resources that will ensure the right production quality and avoid future defects. Once this is done, delve into the reasons of return: broken item, no particular reason, or on the contrary any other. Keep in mind, this metric distinguishes itself from the previous KPI because it focuses on profit by using the net income for its formula. Are you prepared to deal with the unexpected? This is the starting point of your analytics process. At this point the data is already 12-24 hours old. dashboard manufacturing metrics example template tracking source We already covered this metric in some of our other examples, however, it is an important indicator that needs detailed attention on its own. For instance, we can see that machines A and B are working with a low percentage of capacity utilization which is clearly affecting the overall utilization percentage of the organization. Essentially, the OOE is a metric used to track the availability of general production lines from beginning to end. Machine status and performance against targets are examples of the kind of information. For example, you can be confident about adjusting equipment or open new lines to increase throughput at the right time. You can see whats working, and whats not, where the bottlenecks are, and much more. We continue on the right side, where the dashboard shows quality and performance, the production volume, and on-time delivery metrics, depicting the current month, previous month, and the comparison between both. Operating without them makes conceptualizing hard numbers more difficult and opens up the chance of missing patterns that would be more obvious if visualized.

First, lets consider how supervisors, managers and directors get their production performance information without a real-time dashboard. This is a reliable method of production, but it is often a slow and inefficient one. Get our last updates and news directly into your inbox. Use our dashboards as templates, connect your data sources, easily set up and customize your visuals, and try our dashboard software for a 14-day trial, completely free! InetSofts strong data source adapters bring otherwise incompatible data together for powerful ad hoc reporting and multi-dimensional analysis. With help of the insights, you can reduce material costs, increase productivity and plant utilization, and improve product quality. Color-coding makes it quick to see if production is running as planned, or if a machine, for example, is going through planned or unplanned downtime. Instead, you need to include areas such as scheduling, budgeting, operational performance, and logistics (to name but a few) to function as part of a well-oiled machine to remain profitable. If you want to take your manufacturing company onto the next level, datapine is right here to help. Measuring the rate of returns you have is a must-do, to evaluate how performant you are at delivering what you are expected to.

Indeed, right first time is the percentage that will help you win extra points with your clients: not only will they be satisfied to have what they want directly, but that will also give them no reason to complain about your services. For example, a Vice President might be interested in KPIs that affect monthly results, such as cost reductions or risk management. Thats why generating professional dashboards is critical in this machine-focused industry where even the smallest amounts of data can make a big difference. Manufacturing dashboards are able to take this information and remove the clutter giving you the insights that help you make better decisions. Moving on, we have the first pass yield (FPY). The data-driven visualization enables decision-makers to readily understand what is important to focus on at any given moment. With a manufacturing dashboard template gathering your most important metrics related to cost management, you can take a deep breath and relax - all you need to monitor is here. It is similar to the overall equipment effectiveness (OEE), but they differ in the scope they measure. How to Optimize Material Flow with Data Analytics and Machine Learning. Manufacturing dashboards present data and insights from machines, sensors, and systems in a user-friendly way. The evolution over time should be a decrease, as, generally, practice will grow while equipment investments will decrease. This industrial dashboard starts with the effectiveness that covers overall operations (OOE), equipment effectiveness (OEE), total effective equipment performance (TEEP), and capacity utilization. Manufacturing and industrial companies face challenges of globalization.

In this case, we can see that the revenue is around 20% higher than the previous month, but not only, as the revenue per employee and per item increased as well. ezdatamunch utilization Real-time manufacturing dashboards change this completely. They know the previous days output and OEE numbers but that is of little help in maximizing todays COVID-19 made working from home and digital collaboration new norms in enterprises. These metrics are organized just like the previous ones, with comparisons and milestones between the current and the previous month. Collecting a comprehensive history of product batch data is the first step to improve the performance of any process. Want to learn more about how our dashboards can help you, please contact us. Parallelizing that production volume to the quantity ordered is another interesting move: you can see if you manage to keep up with the flow, or if your factory is totally overflowed and has a hard time facing that demand. This enables everyone to react faster to changes in the manufacturing or supply chain environments.

At first, maintenance costs can make up for a big part of your budget; but the idea is to lower them in the long run. But theyre not. The line dashboard above is a one-stop shop for production insights. analytics dashboard manufacturing efficiency operational expenditures reduce improve capital manufacturers cloud based compliance utilization goals showing Lets take a look how you can ease your strategic initiatives with a high-level KPI dashboard next. Emerging technologies like advanced analytics and AI are transforming the world of manufacturing. Here it makes sense to investigate why, although the deviations are only 1%. A manufacturing dashboard is a real-time visual representation of a manufacturing process. When it comes to this production dashboard, you need to know about your equipment. They help manufacturers monitor and optimize production quality and efficiency. When talking about costs in manufacturing, maintenance makes up for an important part. The second aspect of quality that is assessed on this manufacturing dashboard example is the defects.

InetSoft Technology Corp. In essence, its important to keep your production dashboard system clear so that you deal with fewer issues later. What they produce over time will let you know the importance of each of them, so that you can take extra care of the most productive ones. sciemetric Real-time line visibility is critical for efficient operation. The Line Dashboard consists of customizable elements or sections, letting you mix different metrics and visualizations for those metrics in the same dashboard. Similar to this metric is the return on asset, which measures the capacity of your organization to generate profit for each dollar spent on asset. dashboard performance manufacturing examples sales financial dashboards inetsoft visualization analytical analytics bi banking easy analysis business bank sample report industry It is simple to use and it is absolutely brilliant if you are needing dashboards on custom objects." Setup only takes one minute. Using KPIs to track business objectives not only forces teams to ground themselves in data but empowers them to engage in a cycle of continuous improvement. kpi insightsoftware manufacturing dashboard dataself This creates new opportunities in the industrial, social and environmental fields. The KPI History Dashboard offers an excellent way for users to track key KPI trends in operations over time. This number should be as high as possible as this can give a company a great competitive advantage. Imagine driving a car where the dashboard reports yesterdays speed and distance covered. Timely and secure exchange of information with partners is also critical. For many plant managers, factory is a black hole. On this second manufacturing dashboard template, 4 metrics are displayed. by Anna Goeva | June 17, 2022 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | March 3, 2022 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | January 24, 2022 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | December 13, 2021 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | December 1, 2021 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | November 4, 2021 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | October 27, 2021 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | August 20, 2020 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | August 10, 2020 | Blog Posts, Featured | 0 Comments, by Tanja Rauniaho-Mitchell | May 13, 2020 | Blog Posts, Featured | 0 Comments. Managers will get notified immediately if a defect flares up again. A manufacturing dashboard helps to monitor the most important production KPIs in one central point of access. They will help you to accurately forecast, plan, and schedule various parts of the production process and provide a stable manufacturing operation for your customers. In fact, they are able to integrate the data from various sources (such as ERP, MES, automation system, and even Excel files) into a cloud repository. A well thought out series of metrics, along with a program to manage them, help companies achieve organizational agility. dashboards downtime defects analytics kpi scraps dundas metrics inetsoft Essentially, they know when work orders and materials enter the factory and when finished goods leave, but they dont know whats happening in the production. Instead, the world has gained a lesson in the ripple effects of disruption. It helps to monitor the most important production KPIs in one central point of access and to keep the whole team aligned. Dashboards help you do precisely that. Also, production meetings are more effective when you have the right information to hand! Now that vaccines are being rolled out globally and effective treatments seem to be on the horizon, there may finally be faint hints of light at the end of this long tunnel. It is an important aspect to take into account because it deals with the core of your business. Even though enterprises have invested in ERP and MES systems to alleviate the problem, they have not been able to unlock the needed data to know what is really happening in their operations, what the inefficiencies are etc. Through dashboards, organizations can quickly see their current and historical performance. All metrics displayed on it are monitored daily and in real-time to allow manufacturing managers to supervise the performance of their production at a glance. In this blog post, we show you the manufacturing dashboards that provide you the insights and awareness you need to optimize your production. A manufacturer with an R&D unit based in the US as well as manufacturing sites located globally needs to have closed-loop information exchange to quickly bridge the gaps between design and production. Management gets their metrics-related production information from the previous shift or day. datapine dashboard Businesses are more and more globalized and resources and functions are scattered, needing smart data analytics in a collaborative environment. Producing in quantity is good, but only if the quality follows: otherwise, you will never have returning customers, your brand image will be harmed and demand wont come in anymore.